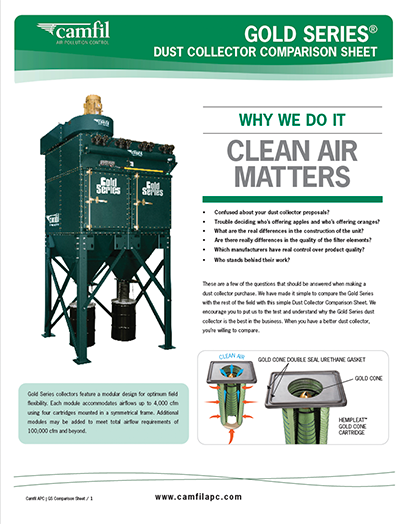

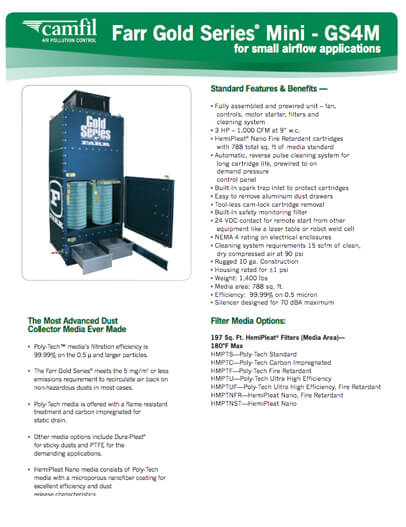

INDUSTRIAL DUST COLLECTORS SAFELY REMOVE TOXIC AND COMBUSTIBLE DUSTS FROM YOUR FACTORY OR SHOP

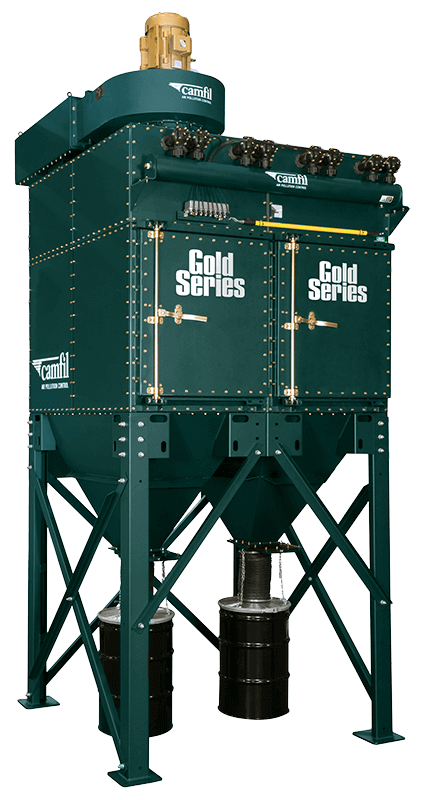

Gold Series industrial dust collectors are the industry’s best-in-class dust collection systems. The family includes Gold Series and Gold Series X-Flo collectors, which have a 25 year track record of successful performance around the world. They handle all kinds of toxic and combustible dusts, smoke and fumes, including fine, fibrous and heavy dust loads.

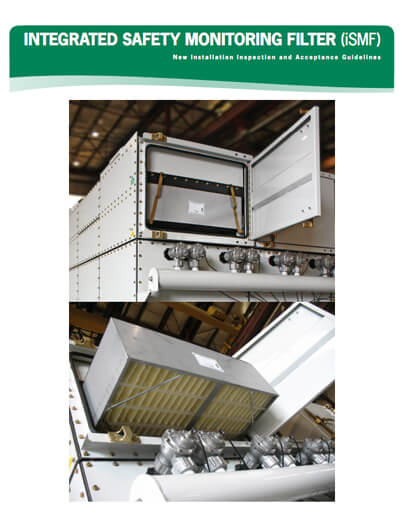

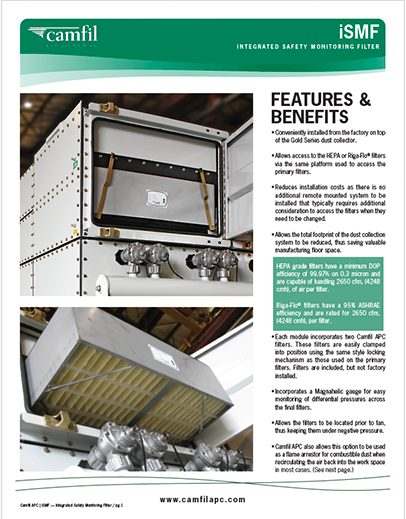

Gold Series industrial dust collectors effectively process dust while maintaining a low pressure drop. And most importantly, they exceed OSHA mandates for factory air quality. When equipped with Camfil’s explosion protection equipment such as explosion vent, iSMF (Integrated Safety Monitoring Filter), and Stinger explosion isolation valve, the Gold Series family offers the highest combustible dust explosion protection in accordance to both NFPA and ATEX standards.

KEY FEATURES OF GOLD SERIES INDUSTRIAL DUST COLLECTORS

Engineered to protect workers from occupational exposure and combustible dust explosions. Delivers the maximum CFM of clean factory air.

Safely contains combustible dusts. Gold Series collectors with explosion protection systems exceed NFPA and ATEX standards.

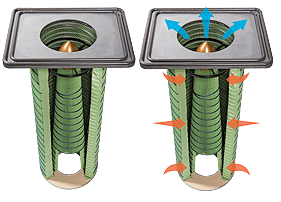

Crossflow technology creates a uniform airflow so filter cartridges last longer.

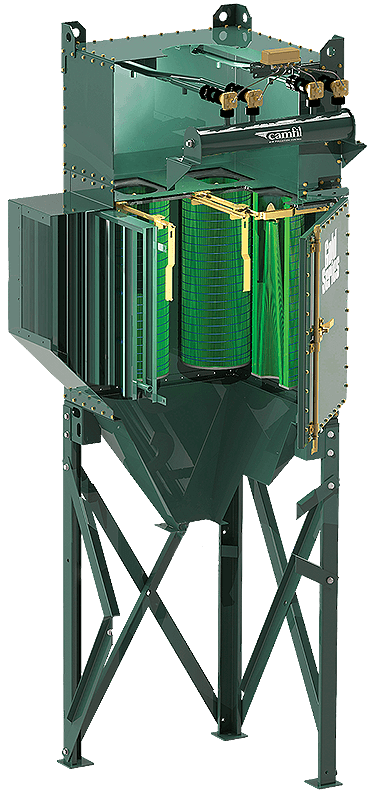

Gold Cone filter cartridges are positioned vertically for superior release of high-loading dust with pulse-cleaning. They deliver maximum airflow and efficiency.

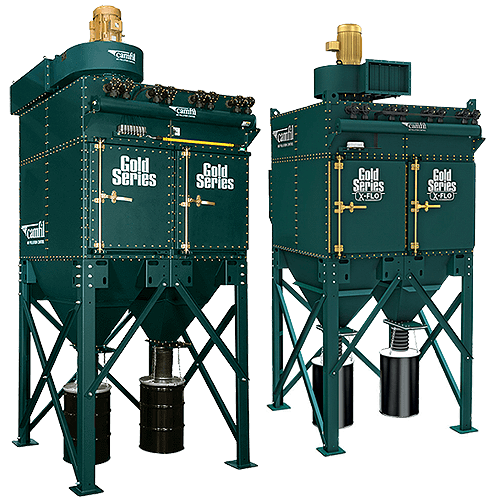

GOLD SERIES

GOLD SERIES X-FLO

THE INDUSTRY’S LOWEST COST OF OWNERSHIP

Gold Series industrial dust collectors use crossflow technology to create a uniform airflow that extends the life of your filter cartridges and minimizes energy usage. Filters last longer and require fewer change-outs, reducing your total cost of ownership. All Gold Series collectors are built modularly, and GS X-Flo collectors accommodate higher capacity filter cartridges in each module for a better industrial dust collection system.

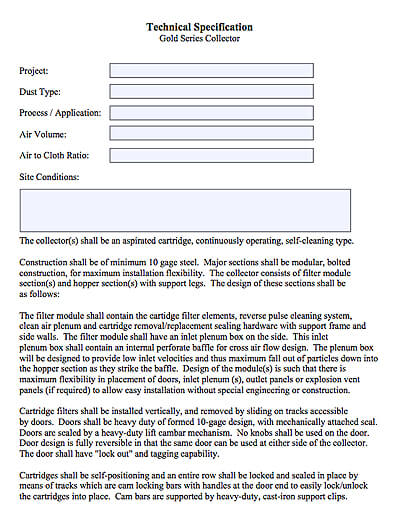

Gold Series Dust Collector Overview

Gold Series X-Flo Dust Collector Overview

1-Minute Demo: What is Pulse Cleaning?

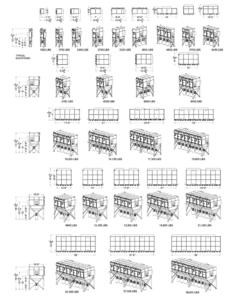

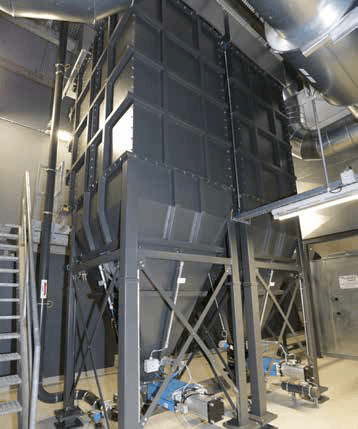

MODULAR DESIGN

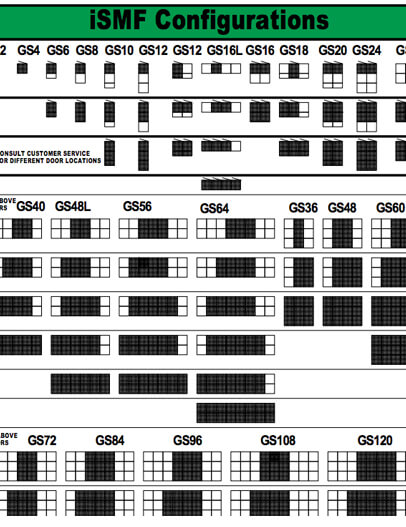

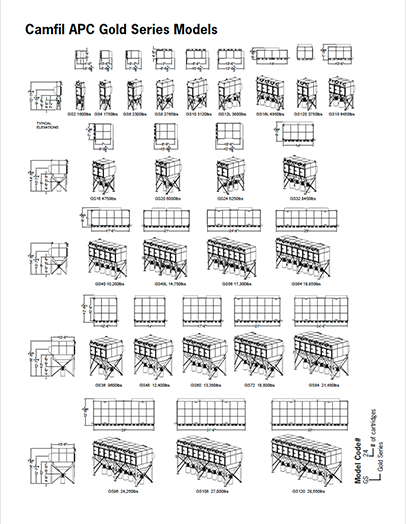

It’s easy to customize Gold Series industrial dust collectors for your specific work environment. Individual modules contain four filters and accommodate airflows up to 6,000 CFM each, providing a near-limitless variety of configurations and airflow capabilities. You get fast delivery of an industrial dust collection system that is just right for your application and space. It's ideal for collecting dust from the manufacturing and processing of dry bulk powder.

MORE FILTER MEDIA, SAME FOOTPRINT

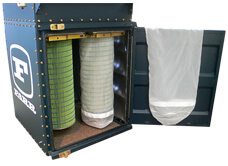

HemiPleat Gold Cone™ filters use our proprietary Gold Cone inner pleat pack. This open-bottomed, inner cone of media greatly expands the usable surface area of the cartridge. HemiPleat technology is our unique approach to creating highly efficient pleated filter media that exposes more media to the airstream, so more dust is loaded on the filter and then released when pulse-cleaned.

VERTICAL FILTER CARTRIDGES

Gold Cone™ filter cartridges are positioned vertically in the dust collectors. This means dust won't fall onto the filters below on its way to the hopper. With each pulse of compressed air, the dust and debris is ejected out of the filter cartridges, and gravity pulls it down into the hopper.

BUILT TO PERFORM

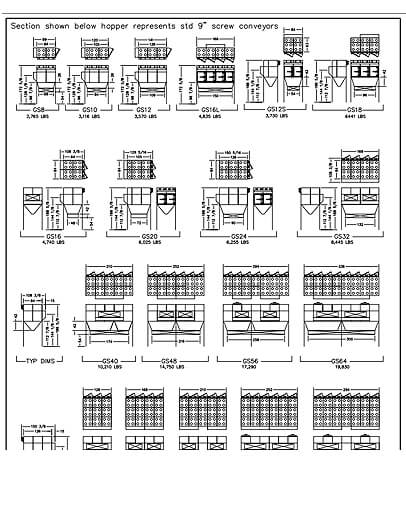

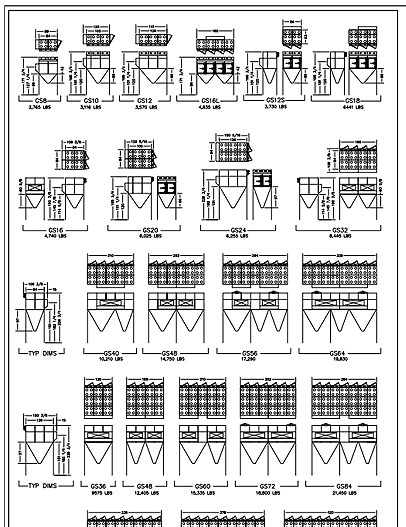

Gold Series industrial dust collectors have a modular design for maximum flexibility. Each module accommodates airflows up to 5,000 CFM each. Component configurations are virtually unlimited.

Gold Series industrial dust collectors have a modular design for maximum flexibility. Each module accommodates airflows up to 5,000 CFM each. Component configurations are virtually unlimited.- Explosion venting

- Rotary airlock

- Drum cover kit

- Clean air chamber access

- Custom colors

- NEMA 7/9

- Solenoid enclosure

- Compressed air regulator

- Leg length

- Solenoid heater

- Outlet weather hood

- Extra cartridge access door

- Hopper access door

- Skid packages

- Stinger explosion protection valve

- Sprinkler system

- Dust level indicator

- Dustbin with drawers

- Common trough hopper

- Low Pro/Low Boy hoppers

- Stainless steel construction

- Various inlet designs

- Platform and ladder

- Self-dumping hopper

- Screw conveyor

- Integrated safety monitoring filter (iSMF)

- Pharmaceutical options

- Customization for specific applications

- Overbags for fibrous dusts like paper and fiberglass

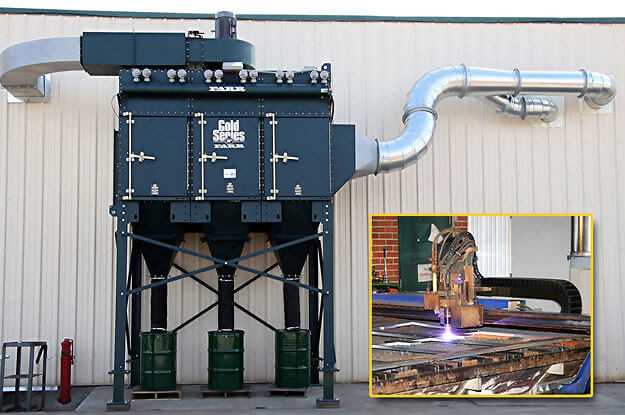

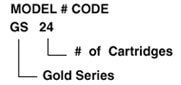

A GS24 with platform and ladder, silencer, blast plate, and custom door setup.

GS24 model with explosion vents and integrated HEPA filter.

Gold Series with directional explosion vent and integrated SMF.

Multiple GS units with platform and ladder options and explosion vents.

- Metalworking – Abrasive blasting, laser & plasma cutting, thermal spray, welding

- Pharmaceutical – Tablet coating, tablet pressing

- Food & beverage – Seed processing, cereals, spices, grains, flours, starches

- Chemical processing – Plastics, paper, fiberglass, other composites

- Mining – Copper, rock crushing, venting of storage, excavating.

Americas

Americas