DUST COLLECTORS FOR THE WOODWORKING INDUSTRY

When woodworking or manufacturing wood products like furniture, one often overlooked danger is wood dust. These tiny particles of wood fiber present two major threats if left unchecked in the woodworking environment:

- 1. They can infiltrate workers' respiratory systems, causing a range of health problems.

- 2. They contribute to environmental pollution, worsening respiratory conditions within the wider community.

Woodworking shops aiming to uphold sustainable practices need to minimize dust exposure and minimize environmental impact.

To maintain a clean and safe work environment, airborne wood dusts must be captured before they can be inhaled by workers. Some wood dusts are recognized as potent allergens, so they require stringent exposure limits to protect workers.

After the wood dust particles are removed from the air, they must be safely contained so they do not cause combustible dust explosions. This is done by constantly circulating the dust-laden air through an industrial dust collection system to filter out the particles. After the dust is removed from the air, the clean air is safely returned indoors or exhausted outdoors. A well-designed and -maintained dust collection system cost-effectively captures and contains all airborne particles.

- Modular construction – easy to build and assemble in limitless sizes and configurations

- Tested to meet NFPA & ATEX standards

- Available with numerous explosion protection options

- Exceeds OSHA mandates for factory air quality

- Less pulse-cleaning of filter cartridges is necessary, so the filters last longer and require less frequent changeout

- Smaller footprints are possible because each unit handles more airflow

- Ships in as few pieces as possible for fast delivery

- Easy installation, operation and maintenance

- Built on 20 years of reliable field dust collection performance

- Gold Cone® filter cartridge contains 375 square feet of media, offering the industry’s highest air-to-cloth ratio

Common Dusts and Concerns:

Wood processing creates dust that can be explosive. Dust collectors minimize the amount of combustible dust that can collect on floors and other surfaces, and they contain dust in one area. But the dust collectors themselves can be a fire or explosion hazard if they are designed incorrectly or not equipped with controls that prevent deflagration and contain explosions. All Camfil APC dust collectors safely contain combustible dusts and are equipped with deflagration controls.

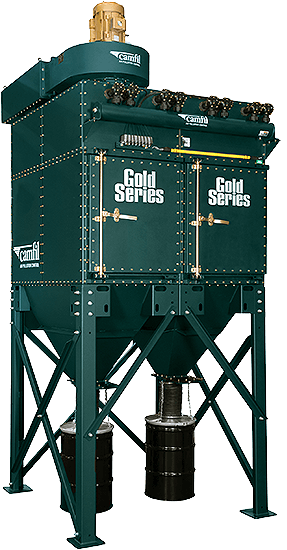

Gold Series dust collector that is correctly fitted with all necessary NFPA devices per NFPA 664, 654, 652, 69, and 68.

Resources and Literature:

GOLD SERIES INDUSTRIAL DUST COLLECTOR

The Gold Series dust collector performs well in applications where dry materials are batch mixed, conveyed and processes. It offers high performance, a modular design, ease of service, and an optional bag-in, bag-out filter change out. Constructed from heavy-duty carbon steel to meet the demands of your application, this collector has unparalleled strength and life compared to the competition. Coupled with Gold Cone™ vertical cartridge technology, Gold Series dust collectors offer superior pulsing of high-loading dust while simultaneously utilizing minimal floor space.

Americas

Americas