Handling Hazardous Dust with Cleanliness, Safety and Efficiency

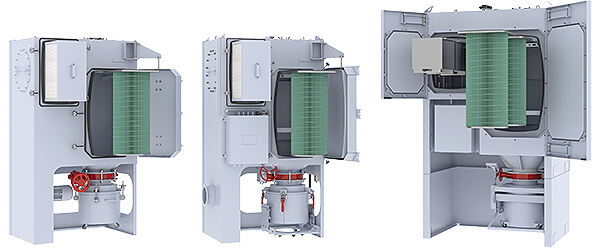

Many processes in the pharmaceutical and chemical industries produce high concentrations of hazardous dusts. Cleanable filter systems make it possible to have continuous manufacturing processes and prevent regular, expensive filter replacements. The Quad Pulse Package (QPP) cleans filters in four segments, one at a time so that they are continually cleaned without interrupting airflow. And the QPP is now available with two filter cartridges for higher air volumes. Its compact design features easy installation, bag-in/bag-out process for the primary/secondary filters and discharge bin. Both units are explosion pressure shock resistant without the need for additional protection systems.

QPP 1

QPP 2

Key Features Video

The system pulses one quadrant at a time so that the dust collector is always online and air flow is never interrupted.

The system pulses one quadrant at a time so that the dust collector is always online and air flow is never interrupted.

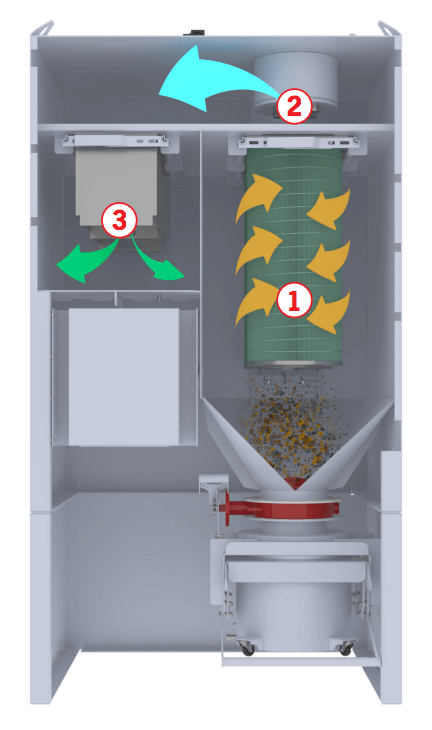

EFFICIENT FILTER STAGES

Stage 1: Primary filter with excellent filtration efficiency removes the majority of collected dust and prolongs the service life of the second stage filter.

Stage 2: Quad Pulse cleaning system.

Stage 3: HEPA filter up to H13 providing 99.995% filtration efficiency to capture the finest, most hazardous dust particles.

Stage 4: Discharge bin.

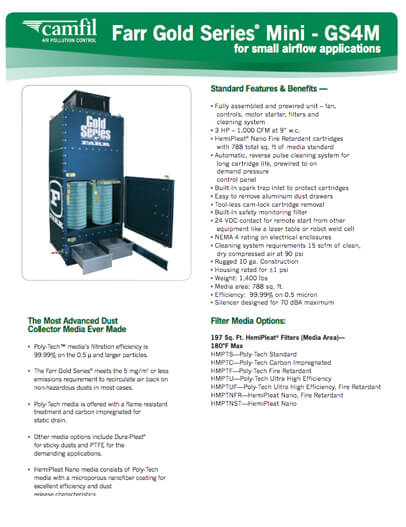

COMPACT DESIGN, SMALL FOOTPRINT

Space on the production floor and in the plant is at a premium. The ATEX and NFPA compliant explosion protection capabilities of the device enable the Quad Pulse collector to be conveniently installed indoors with easy access for all maintenance functions.

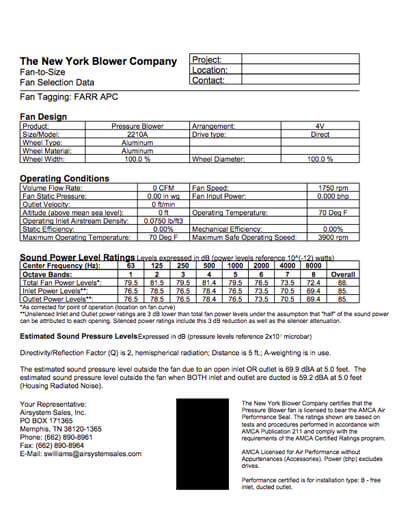

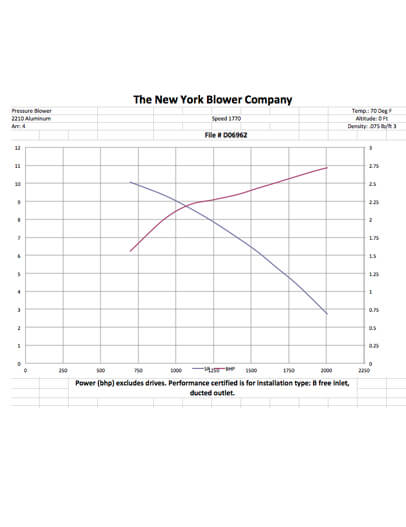

HIGH PERFORMANCE, LOW NOISE

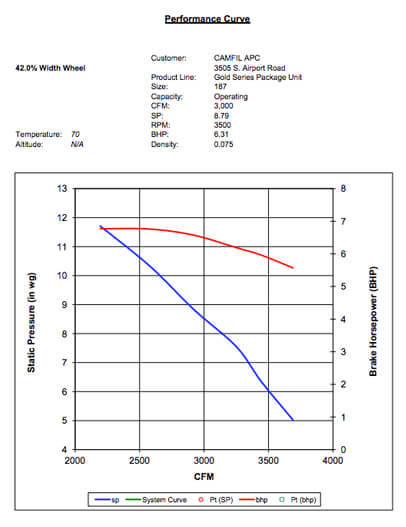

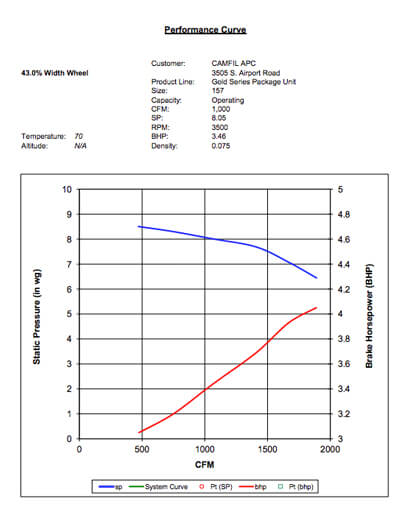

The integrated fan (QPP1) can provide the suction required for each individual application. At the same time, the unit is insulated to make it very quiet during operation.

BIBP Safe-Change Primary Filter:

- Utilizes the market-leading Camtain methodology with an antistatic BIBO bag, providing a full containment solution to protect workers and prevent cross-contamination.

BIBO Safe-Change HEPA Filter:

- Uses the Camtain system for straight forward BIBO filter change.

- Ensures full containment of the finest most hazardous dust particles.

BIBO Safe-Change Dust Discharge:

- Collected dust is removed quickly and easily with full containment.

- QPP1: 9 GAL BIBO DRUM; QPP2: 13 gallon BIBO drum serviced from the front.

The Quad Pulse Package HEPA filter captures the fine dust particles and is a tested flame and contamination barrier. Key advantages:

The Quad Pulse Package HEPA filter captures the fine dust particles and is a tested flame and contamination barrier. Key advantages:

- The pressure shock resistant housing maintains its integrity with no damage during an explosion event.

- The Quad Pulse HEPA filter captures fine dust particles and avoids the need for costly add-on explosion protection.

- Additional, expensive explosion safety devices may not required within given limits.

- Compact unit with flexibility for indoor installation reduces the need for long duct runs.

Additional Information

Applications:

- Tableting

- Filling

- Coating

- Granulating

- Drying

- Mixing

- Blending

- Packaging

- Central vacuum

Advantages:

- Clean online without interrupting operations

- Explosion pressure shock resistant

- Uniform flow-through and cleaning of the cartridge

- Longer filter life/reduced filter change-outs

- Compact design with just 1 or 2 filter cartridges

- High energy efficiency

- Innovative filter material allows highest separation rates

- Reduced back-pressure to upstream processes

- HV- Applications

Americas

Americas