Mist Collector Solves Coolant Mist Problems

Applications:

- Grinding

- Cutting

- Drilling

- Etc.

High-end, high-efficiency, modular coolant mist collector

With advances in technology, machine tool productivity and accuracy continues to improve. As a result, there's an increasing need to collect ultra-fine mists and fumes. To ensure worker safety, production efficiency, and the protection of capital plant and equipment, compliance with workplace exposure limits cannot be compromised. The EM Expert provides optimum results even in the most challenging conditions.

- Economically efficient separation of ultra-fine coolant mists and fumes

- Collection efficiencies at 99.97% on 0.3 micron and higher particle size with the optional HEPA final filter

- Long-life filters

- 24/7 operation

- Airflow can be adjusted without affecting the collection efficiency

- Operator-friendly due to low-maintenance design

- Long filter life with minimal maintenance requirement

- Optional clean air recirculation

- Plug-and-play delivery

Key Features:

- Highly efficient, multi-stage filtration

- Flexible and modular design

- Multiple units can be combined for any size application

- Self-cleaning filtration media

- Long filter life with minimal maintenance requirement

- Optional HEPA filter

Cascade collector design with ascending filter classes allows filter combination matching for the specific machining process.

FAN

Integrated or top-mount fans provide reliable, constant extraction power to meet the application requirements. With integrated fans, acoustic insulation is included in the housing. The units are delivered ready for plug-and-play without any additional assembly required at the installation.

FLUID RETURN

Due to the self-regeneration design of the filter elements, the separated cooling lubricant is released from the filter media and drains to the fluid return sump at the base of the unit. Through either a recirculation pump or siphon, the collected coolant can be returned for treatment, reuse or disposal.

FILTER CASSETTE WITH MEDIA SEPARATORS FOR MAXIMUM FILTER AREA - The CoaPack filter element provides maximum filter area within a compact design. This construction ensures a uniform flow, optimum use of diffusion and coalescence, which is a relevant separation mechanism for ultra-fine mists. The small load acting on the filter surface reduces the energy consumption and significantly increases the service life of the filter element.

IDEAL DRAINAGE PERFORMANCE FOR OPTIMUM FILTER REGENERATION

The premium filtration effectiveness is due to the ideal balance between separation performance and regeneration of the separated emulsion lubricant from the filter media. This is achieved by using drainage-friendly materials together with special drainage support mats, protective screens, and spacers.

CLEAN MAINTENANCE, EASY FILTER CHANGE

Thanks to its functional design, the EM Expert is practically maintenance-free. Quick-acting clamps ensure that changes of the filter cartridges are easy and require no tools, ensuring minimum downtime. Filter cartridges are accessed via the service door(s) and a transport trolley is available, providing drip-free removal of the filter cartridges—a perfect complement to our service concept.

Top Element Modules

1. Connecting box - For use with an external fan. For optimum flexibility, the ductwork to the external fan can be connected to either side.

2. Top mount fan - For use in connection with a downstream silencer.

HEPA Final Filter

3. Final filter stage - Available as an option for particulates less than 1 micron, such as smoke, and to recirculate the air.

Main Filter Stage Module

4. Main filter stage

For CoaPack diffusion filter cartridges and use of a coarse filter stage for high contamination or clean air recirculation.

Bottom Element Modules

5. Fluid collector for installation on platforms. Vertical cooling lubricant discharge via siphon or gravity.

6. Fluid collector with recirculation pump station - Use if discharge by gravity is not feasible or for feeding into the cooling lubricant recirculation supply for the machine tools. Integrated pumps are available in two sizes.

7. Fluid collector for floor installation - Discharge of the cooling lubricant through a siphon and by gravity.

Fast-acting clamps ensure easy filter changeout, and the available transport carriage provides drip-free removal of the filter cartridges.Customizable to Fit Your Needs

By combining different basic modules, it is possible to design economically efficient central extraction systems of 41,000 CFM and more.

- Component design flexibility for customized application

- Minimum space requirement, maximum performance

- System can be expanded in the future as needed

- Short delivery time

- Easy transport and installation

Got a problem with coolant mist? Call in the EM Expert.

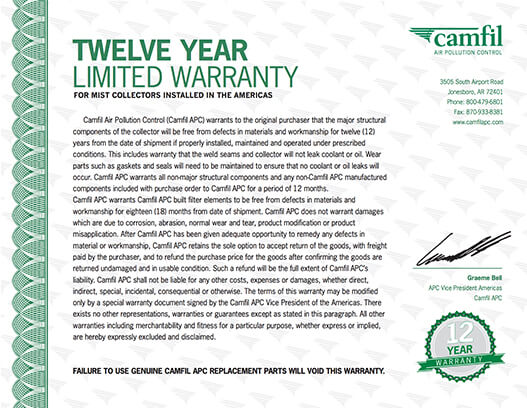

No Leaks – Guaranteed

German engineering and American manufacturing expertise result in premium quality products. We guarantee that our mist collectors will not leak.

Download our 12-year limited warranty for details.

Americas

Americas