Managing industrial dust generated across various manufacturing processes is a pressing concern for many industries due to its implications for the environment, health, productivity and safety. The release of tiny particles into the air occurs during activities like drilling, pelletizing, die-cutting, sanding, blending, crushing, mixing and grinding. Key industries are wood, metal, chemical, food, pharmaceutical, construction, paper and packaging.

Dust particles can either become suspended in the air or settle on surfaces, potentially contaminating products and causing harm to manufacturing equipment. Additionally, dust causes poor indoor air quality, posing health risks to workers when inhaled. Over time, this occupational exposure leads to issues such as headaches, skin irritations, and chronic conditions like asthma and lung diseases.

Also, some industrial dust is combustible such as food ingredients, metals, wood, textiles, and pesticides. Combustible Dust particles emitted during processes can increase the risk of workplace explosions if not collected and contained properly. Companies are obligated to adhere to government regulations like OSHA (Occupational Safety and Health Administration), ATEX, and NFPA (National Fire Protection Association) to maintain healthy and safe working environment.

Dust Collectors Improve Indoor Air Quality in Manufacturing and Processing Environments

Dust collection systems removes the particulate that is produced by a manufacturing processes. They do installing proper hooding at the process, then transport the particulate to the dust collector through a series of duct work and then the particulate is separated from the air by filters.

A variety of dust-collecting systems are available on the market to address different requirements. These include:

- Cartridge-style dust collectors – widely used for general-purpose air cleaning with facilities across different industries. These dust collectors use disposable pleated cartridges as the primary filter media.

- Baghouses – capable of removing higher volumes of dust particles. They operate with bag or fabric filters

- Wet scrubbers – use liquid to remove fibers and sticky dust by filter air and dust through rough filtration.

- Portable dust collectors – ideal for isolated jobs to capture dust at the source. Portable dust collectors function similarly to larger systems but on a smaller scale.

Regardless of choice, an important factor in keeping a dust collector operating efficiently over its lifetime is selecting the right filters and media for the dust that the collector will be seeing. Past blog posts discussed how to save on dust collector filters and how to choose the right kind of filter media. Another important factor is ensuring the proper air-to-cloth ratio or filter velocity for the dust that your collector will be seeing. Here’s what you need to know.

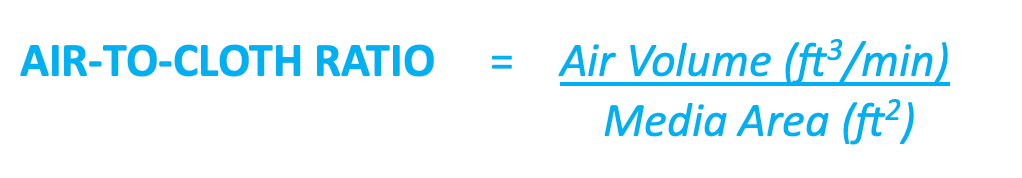

What is Air-to-Cloth Ratio?

Simply put, the air-to-cloth ratio (also called the "air-to-media" ratio) of a filter represents the volume of air flowing through each square foot of filter media every minute. To calculate this ratio for your dust collector, divide the total airflow in cubic feet per minute (CFM) by the total square footage of the filter media present in all the cartridges.

So, a dust collector with airflow of 4,000 CFM over a filter media area of 2000 square feet has an air-to-cloth ratio of 2:1. This means 2 cubic feet of air is passing through every spare foot of filter per media. Determining this ratio is important to ensure proper filter life for your dust collector system.

Determining the Ideal Air-To-Cloth Ratio

The general rule of thumb is that the higher the airflow and dust concentration in your system, the more square feet of filter media you need in your dust collector filter cartridges.

It is important to get your air-to-cloth ratio right. As the air to cloth ratio increases so does the can velocity in the dust collector. The particle size and the loading plays a very important part in sizing your dust collection system. If you’re can velocity is to high then you will not be able to clean the dust off your filters which this is called reentrainment. The result? Filters get clogged rapidly and need to be replaced more frequently, driving up both the cost of consumables and the time and resources spent on maintenance.

And even more important, the velocity at the hooding decreases and promotes low capture velocity, which means the particulate that is being produced at the process will not be captured, which causes a even more dirty environment. It also reduces the conveying velocities in the duct work and could cause the duct system to fail. This could cause the manufacturing process to stop. If you are dealing with combustible dust then you have even more problems.

Impact of Air-to-Cloth Ratio on Operations

Selecting the right dust collector filter with an appropriate air-to-cloth ratio:

- Helps increase filter lifespan.

- Optimizes filter efficiency.

- Achieves the desired level of filtration.

- Supports more uniform loading of filter media for better filtration.

- Cuts costs related to system maintenance as less time is needed to change out filters.

- Prevents unnecessary spending on filter cartridges.

- Increases energy savings and operational efficiency

The wrong air-to-cloth ratio can lead to:

- Excessive airflow, reducing filter life.

- More frequent filter replacements.

- Increased operational costs.

Performance Life Expectancy

All cartridge-style dust collectors are sized based on air-to-cloth ratio to a set performance life expectancy. Performance life is the dust collector’s ability to maintain the design process flow as a dependent on air-to-cloth ratio or filtration rate.

Different styles and different filter element configurations also influence performance life. For example, the dust collection system is responsible for maintaining filter element pressure drop within a given range. When the filter element pressure drop moves above this range, the dust collection system flow will decline, thus losing its ability to maintain the design capture velocity and transport velocity. Without the proper velocities, dust will not be captured or transported to the dust collector.

Ensuring regulatory compliance

Getting the right air-to-cloth ratio also is important to ensure compliance with regulatory standards, especially when it comes to combustible dust particles. Food ingredients, metals, pharmaceuticals, petrochemicals, and pesticides can emit combustible dust. The table below shows combustible dust classifications. OSHA enforces the National Emphasis Program (NEP) that focuses on combustible dust in the workplace.

| Dust Explosion Class | Kst (deflagration index)* | Characteristic |

| St-O | 0 | Not explosible |

| St-1 | <200 | Weak to Moderately explosible |

| St-2 | 201-300 | Strong Explosible |

| St-3 | >300 | Very Strongly Explosible |

*Kst, the dust deflagration index, measures the relative explosion severity compared to other dusts.

In these applications, explosion protection components such as explosion vents and appropriate media filters ensure that dust collectors are built to requirements that meet or exceed regulatory standards. In addition, having the right air-to-cloth ratio in air filtration can eliminate many of these combustible particles.

For example, most manual welding applications require an air-to-cloth ratio between 2.5:1 and 3.5:1, while high-production robotic welding requires a ratio of 1.5:1 and 2.1:1.

Manufacturers creating or handling combustible materials are required to conduct a Dust Hazard Analysis as mandated by NFPA 652. Camfil explains the Crucial Elements to Include in Your Combustible Dust Hazard Analysis.

Consider filter media

Another important consideration when choosing an appropriate filter for a dust collection system is the filter media. Different media used in filter cartridges have different filtering properties, which can affect the ideal air-to-cloth ratio for a specific system.

There are primarily two types of filter media used in the process of dry dust collection. The first is cellulose, a nonwoven blend of cellulosic materials. The second is spun-bond, a mix of synthetic polyester or a polyester silicone blend.

Cellulose is typically the more cost-effective of the two, with a usual blend of 80% paper and 20% synthetic fiber. It is suitable for most applications, demonstrating a relatively high performance even under high-temperature conditions.

On the other hand, spun-bond media is made entirely of synthetic fibers, enabling it to work effectively even at higher temperatures. Notably durable, spun-bond media also demonstrates good resilience when exposed to moisture during the manufacturing process.

Both types of media can be enhanced with special treatments for improved performance, including features like fire retardance, moisture resistance, and the ability to capture nanoparticles. For more filter media information, check out the segment “Dust Collector Filter Media Selection” by Randi Huckaby, Camfil APC’s Product Manager for Dry Filtration, on Camfil’s Let’s Talk Clean Air podcast.

Filter media challenges

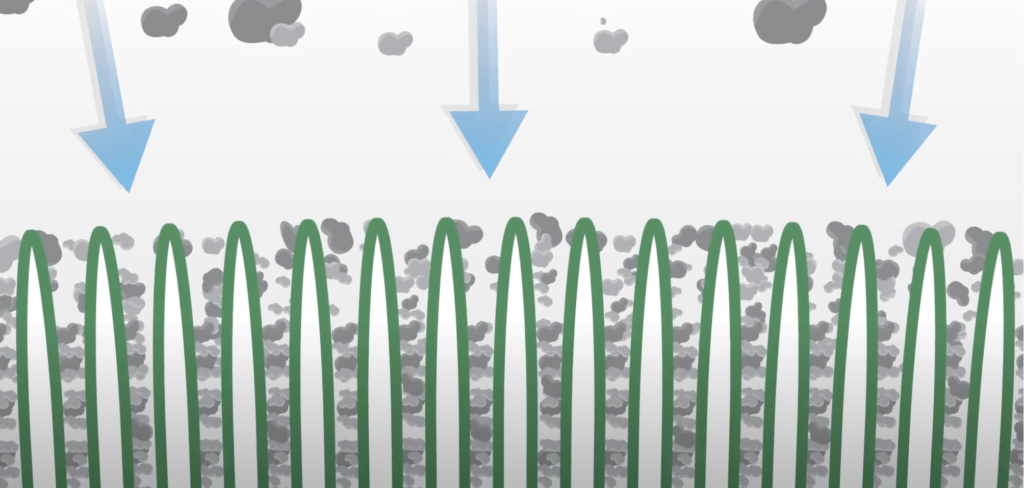

Contrary to popular belief, more filter media doesn't always equate to better performance. Many manufacturers cram as much media as possible into their filters to maximize the square footage within each cartridge. This approach often leads to a filter being so densely packed with media that it becomes inefficient.

When pleats are packed too tightly, a large portion of the media becomes unusable because it is shielded from the airstream and unavailable for filtering. As a result, the filter can't load as much dust, with pulse cleaning becoming significantly less efficient. Recognizing this issue, Camfil, sought to develop a more effective solution for dust collector filters.

Pleating Technology Matters

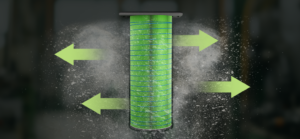

In response to the ongoing challenges of maintaining efficient dust collector filter performance, Camfil created a patented pleating technology known as HemiPleat®. This patented innovation uses plastic bead separators to hold the pleats open and ensure consistent spacing, resulting in a notable increase in filter efficiency.

The goal of HemiPleat technology is to expose more square footage of filter media to the airstream. Strips of plastic beads are added to keep all the pleats more open and evenly spaced. There is more media available to capture dust particles, and it is easier for those particles to be ejected with each burst of reverse pulse cleaning air. This raises the overall filtration capacity of your dust collector and thus its efficiency.

The open-pleat design characteristic of HemiPleat filters facilitates a much higher airflow per square foot of media. This means that more dust can be loaded onto the filter and then released when pulse cleaned. The ability to handle more dust not only improves the filter's capacity but also reduces the need for frequent replacements, providing substantial cost savings.

Moreover, the breathable and open design of HemiPleat filters ensures a lower pressure drop. This is a significant advantage, as lower pressure drop translates to reduced demand on the dust collector's motor, thus resulting in significant energy savings. With HemiPleat’s open pleat design, your dust collector will be able to use every square foot of its media, improving its air-to-cloth ratio.

Additionally, HemiPleat filters help conserve compressed air, which is a critical resource in many industrial environments. By reducing the amount of compressed air used for the pulse-cleaning process, the filters contribute to more efficient operation and further cost savings.

Emphasizing Health and Safety

HemiPleat filters have been thoughtfully designed to foster a healthier, cleaner working environment. The open-pleat design of HemiPleat filters allows your dust collector to fully utilize every inch of its air-to-cloth ratio, optimizing the dust collection process and ensuring the best possible filtration efficiency.

Integrating a HemiPleat filter into a dust collection system leads to substantial savings of time and money. By reducing energy usage and the demand for compressed air, the operational costs associated with a dust collector are significantly minimized. Additionally, by reducing the frequency of filter replacements and related maintenance downtime, HemiPleat filters enhance productivity and efficiency.

But, the ultimate benefit lies in the improved safety and health conditions of the workplace. As a dust collector works more efficiently, the levels of airborne dust and particulates in a facility are reduced, promoting cleaner air and contributing to the overall health and well-being of your employees.

HemiPleat filters are designed to create a safer, cleaner work environment. Users save time and money on energy usage, compressed air, filter replacements, and downtime while dust collectors work more efficiently to keep your employees safe. For help selecting the right HemiPleat filter for your application, speak with a product expert at Camfil APC.

For assistance in controlling the dusts generated in manufacturing and processing operations, email or visit www.camfilapc.com.

Americas

Americas