Filter Pleating Technology That's Guaranteed to Perform

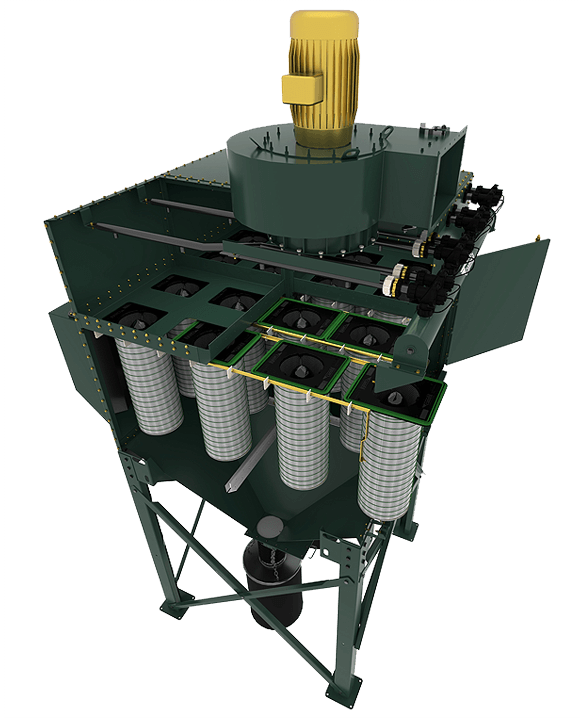

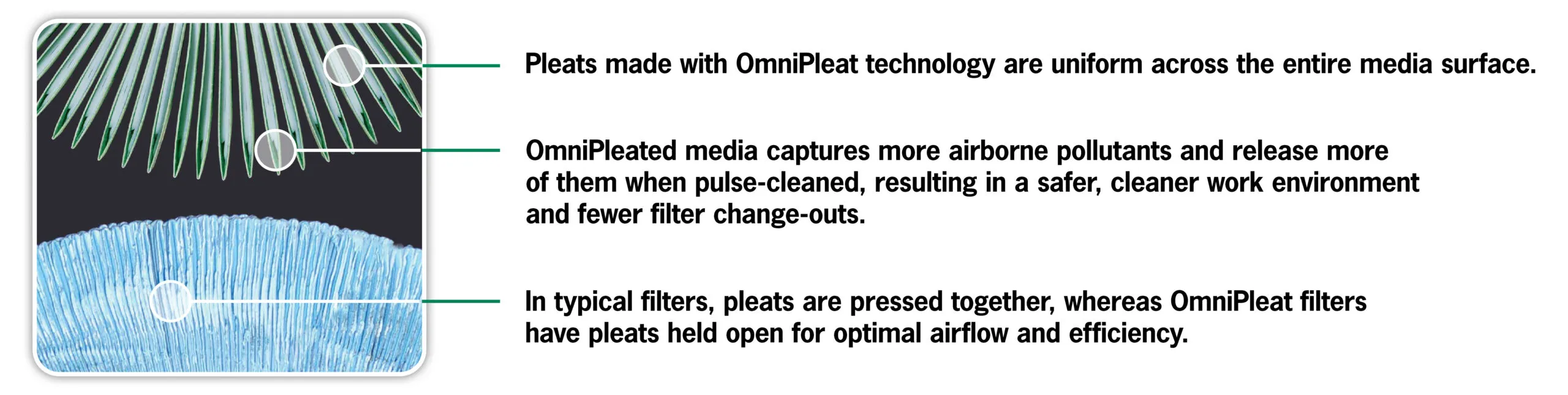

OmniPleat® is Camfil's unique method for producing high-performance filter cartridges. Synthetic, custom-shaped glue beads are applied to both sides of the media pack to hold the pleats open and evenly spaced. This design helps ensure 100% media utilization. In contrast, many standard filter cartridges pack their media too tightly, greatly limiting the surface area exposed to the airstream.

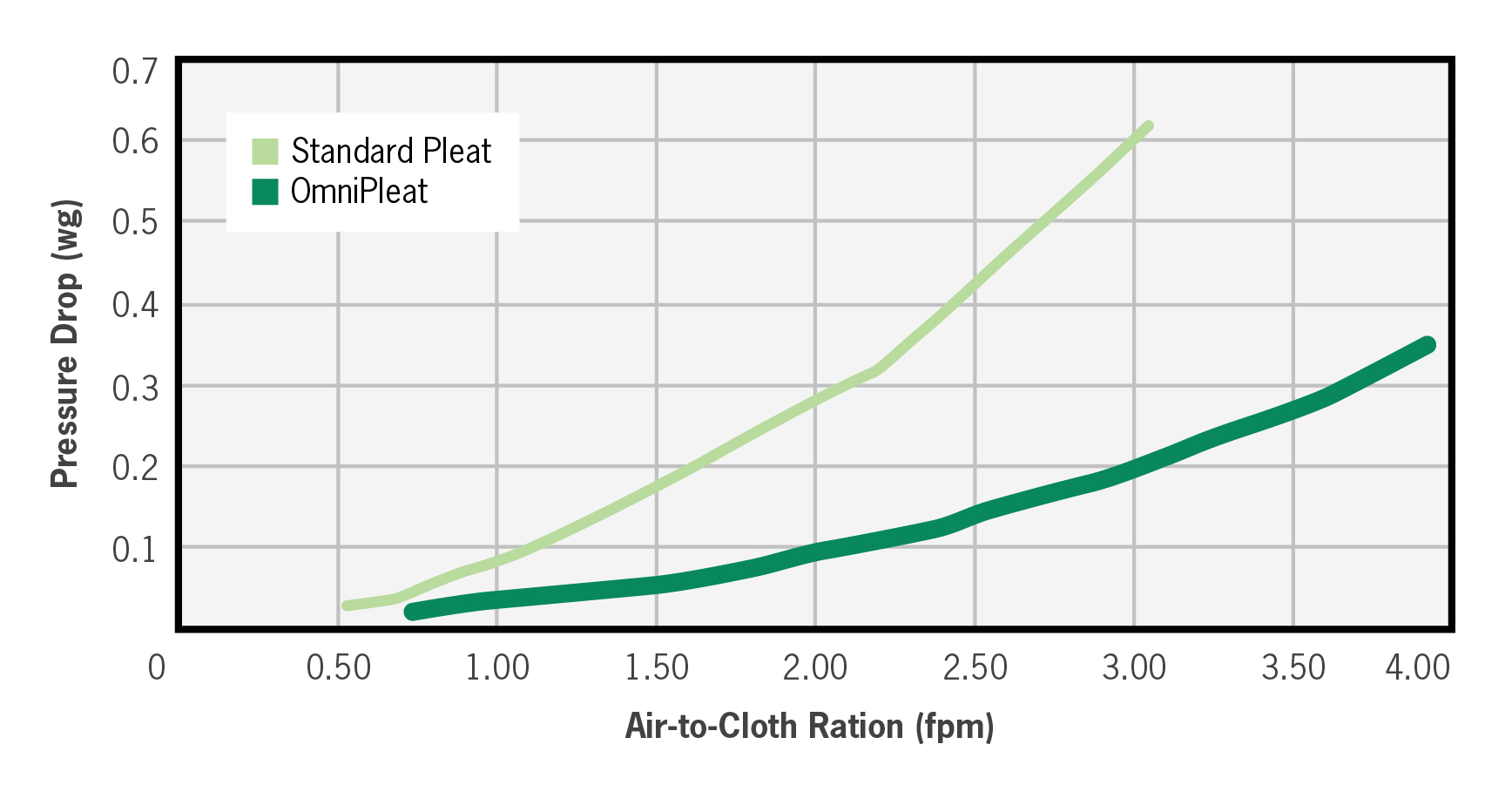

Filters made with OmniPleated media packs deliver a lower pressure drop and release more dust during pulse cleaning, reducing the energy demand on the fan motor and air consumption costs related to pulse cleaning. Camfil guarantees that filters manufactured with OmniPleat technology will last 30% longer than standard filters.

- Efficiency – Up to MERV 16 per ASHRAE 52.2:2017

- Maximum Operating Temperature – 160°F (71°C)

Key Features of Omnipleat Filters

Filters with OmniPleat media exhibit a lower pressure drop at a given airflow compared to standard filters.

Filters that use OmniPleat technology can hold a larger volume of dust before requiring cleaning.

OmniPleat filters have more usable media available for effective filtration.

During pulsing, dust is efficiently ejected from the filter, maintaining long-term performance.

Discover More – Connect With Our Team

Omnipleat Media Options

GR - Standard Green

Cellulose base media - Our own blend of fibers with a moisture resistant treatment for the best dust release, long filter life and MERV 10 filtration.

FR — Flame Retardant

MERV 10 base media with flame retardant resin applied for fire resistance. Our own blend of fibers, chemically treated with a fire retardant.

FC – FR Carbon Impregnated

Cellulose media with fire retardant resin and carbon impregnation for static dissipation - Our own blend of fibers, impregnated with carbon for static dissipation and chemically treated with a fire retardant. MERV 10.

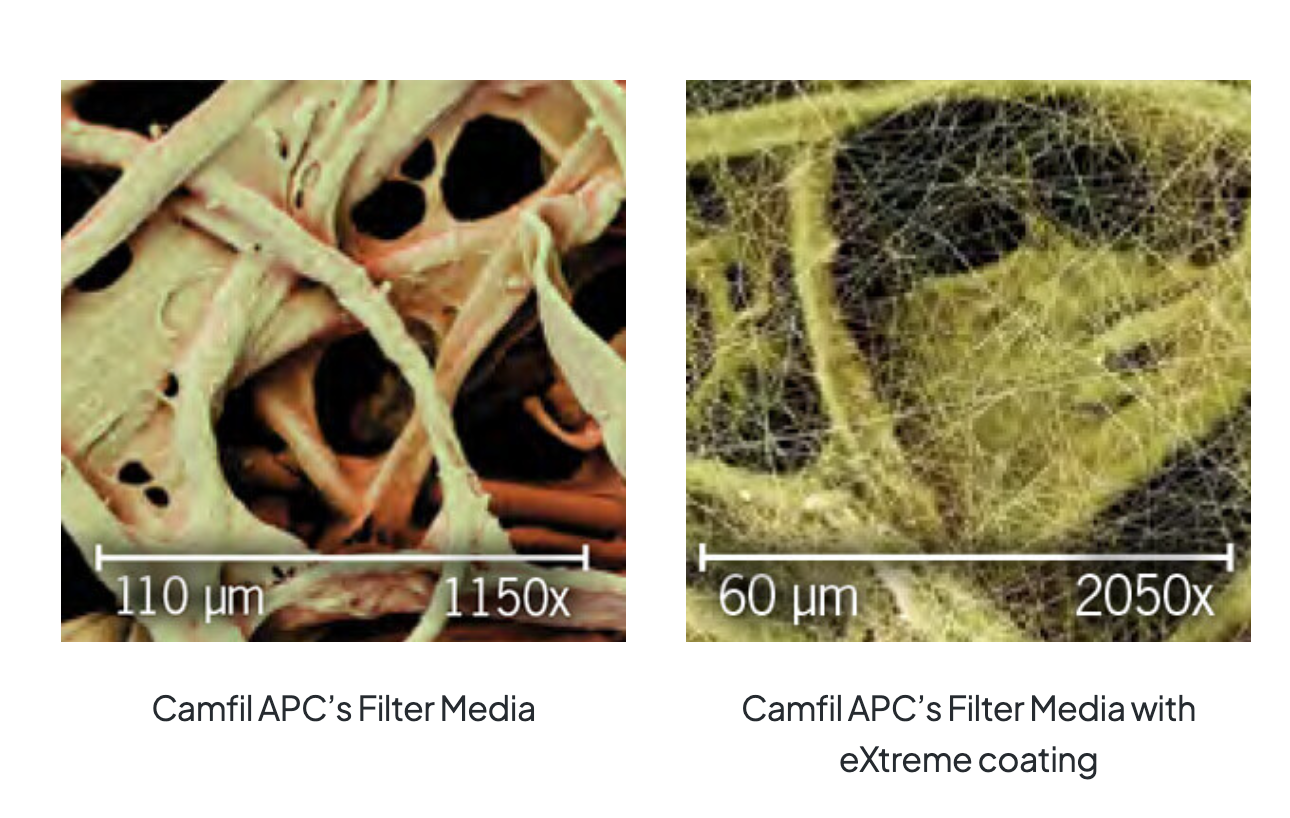

XG — eXtreme Green

Standard green with nano membrane applied for improved efficiency and dust release. MERV 15.

XFC — eXtreme Fire Retardant Carbon Impregnated

Cellulose media with fire retardant resin and carbon impregnation for static dissipation nano membrane applied for improved efficiency and dust release. MERV 15.

XF — eXtreme Fire Retardant

Cellulose media with fire retardant resin and nano membrane applied for improved efficiency and dust release. MERV 15.

XS — eXtreme Synthetic

Lightweight synthetic polyester and nano membrane applied for improved efficiency and dust release. MERV 15.

FRPTFE — Flame Retardant PTFE

A cellulose based media chemically treated with flame retardant and PTFE membrane for high filtration efficiency and best release. MERV 16.

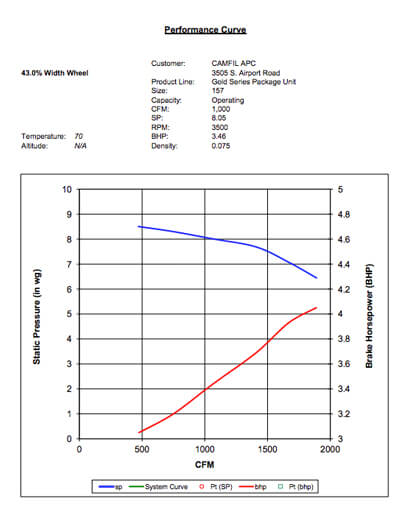

Tested & Proven Performance

Tests Show That Omnipleat Technology Greatly Enhances Pulse-jet Cleaning

Our filter cartridges have been tested multiple times in the lab. Those tests show that OmniPleat technology greatly enhances pulse-jet cleaning.

Filter cartridges with OmniPleat technology capture more air pollutants and release more of those pollutants when pulsed, resulting in a safer, cleaner work environment with less maintenance.

OmniPleat technology provides the lowest initial pressure drop and the lowest pressure drop that lasts through the lifetime of the filter.

For filters made with OmniPleat technology, tests showed that…

- OmniPleat filters have a lower pressure drop for a given airflow.

- Compared to filters without OmniPleat technology, OmniPleat filters hold a larger volume of dust before needing to be cleaned.

- There is more usable media available for filtration in OmniPleat filters.

- Dust is ejected from deep within the OmniPleat filters during pulsing.

OmniPleat eXtreme synthetic filters use our tested and proven OmniPleated base media with an additional layer of nanofibers applied to the media surface. They are rated MERV 15.

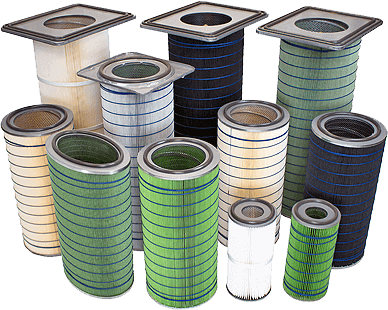

We have thousands of filters cross-referenced and in stock, able to fit units of any size and shape. Our filters will also fit in most OEM equipment and come in a variety of media to meet demanding application requirements. We also carry specialized square, rectangular, jet 3, jet 4, and twist lock top pans.

100% MONEY BACK GUARANTEE

The techniques we use to manufacture the media packs of our filter cartridges are unique and patented. Camfil APC is the only company to offer OmniPleat® technology.

We guarantee that you will receive 30% more filter life than any competitors’ filter by switching to a Camfil OmniPleat retrofit filter. If not, we will give you your money back in full.

Americas

Americas  When it comes to dust collector filter cartridges, open pleats perform better because they expose the maximum amount of media to the airflow

When it comes to dust collector filter cartridges, open pleats perform better because they expose the maximum amount of media to the airflow