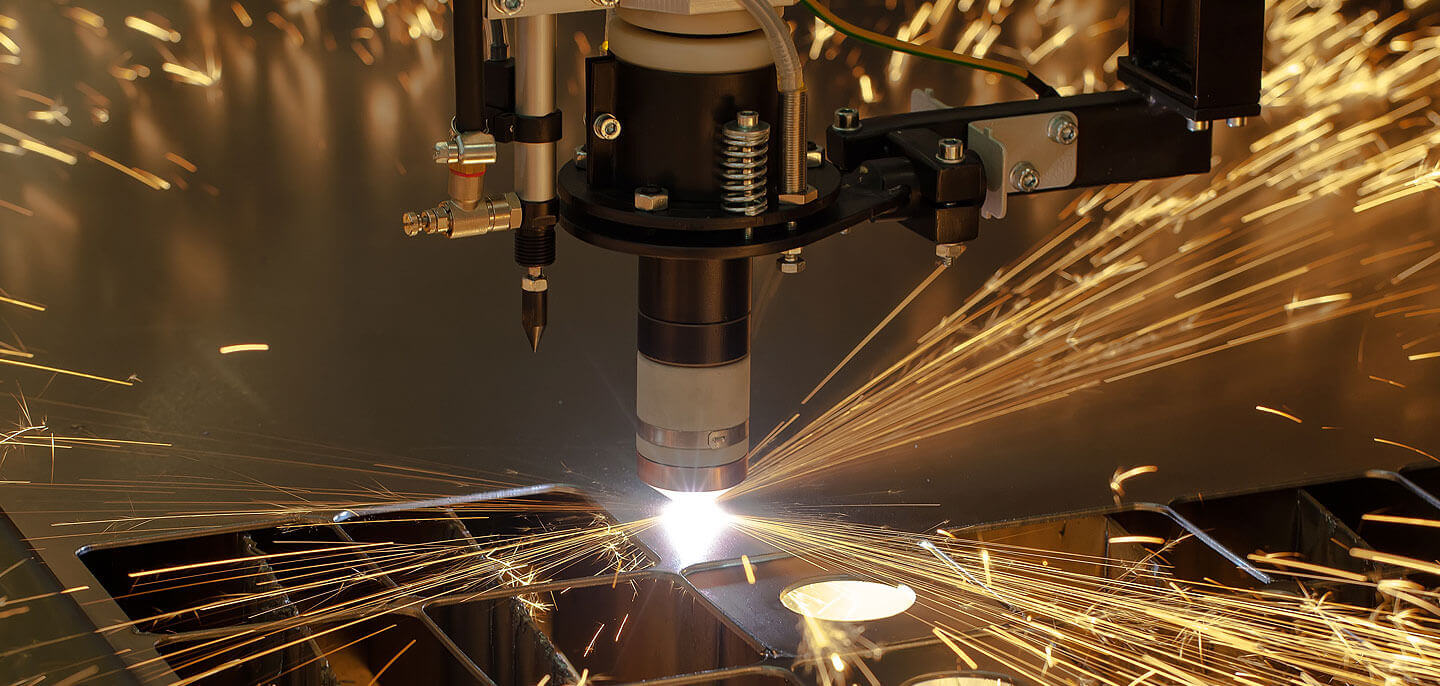

Safely Capture Dangerous Plasma Fumes and Smoke

Plasma cutting is used for a variety of metals, including stainless steel, aluminum and copper. Plasma tables generate molten metal, smoke, and gases which can be breathing hazards for machine operators. Good ventilation is required to prevent inhalation of toxic airborne particles, particularly the tiniest particles that can settle deep into lung tissues.

Plasma cutting dust collection system are most commonly used to capture particles at the source. Dust, fumes and smoke are pulled down through the slats and removed through the duct-work where they are filtered through the dust collector. The dust collector’s filter cartridges capture all particles until they can be safely removed. The sparks and molten metal settle in the area below the slats.

Particle properties, airflow, and loading rates differ widely from application to application, so be sure to consult a Camfil APC expert to size the correct system. Combining guidelines found in the ACGIH “Industrial Ventilation: A Manual of Recommended Practice for Design” with our in-field experience and state-of-the-art filtration, Camfil APC will correctly size a cost- and space-saving filtration system that is reliable, durable and easy to maintain.

Download the White paper today

This white paper will discuss some of the safety and operational problems inherent in “wet” systems, the advantages of “dry” filtration, and how to arrive at an informed purchasing decision.

Learn this and more in the FREE White Paper

Resources and Literature:

GOLD SERIES X-FLO® INDUSTRIAL DUST COLLECTOR

The Gold Series X-Flo Industrial Dust Collector (GSX) is a robust plasma cutting dust collection system that will rid your work environment of harmful fumes and smoke from plasma cutting. The collector features a modular design so that it can be sized for specific applications and occupy the smallest possible footprint. Individual modules accommodate airflows up to 6,000 CFM each, providing a near-limitless variety of configurations that can be delivered weeks faster than any other brand of dust collection system. All GSX collectors feature heavy-duty carbon steel construction and thermal cured powder coatings for unparalleled strength and durability. They combine enhanced performance with ease of service.

- Modular construction – easy to build and assemble in limitless sizes and configurations

- Tested to meet NFPA & ATEX standards

- Available with numerous explosion protection options

- Exceeds OSHA mandates for factory air quality

- Less pulsing of filter cartridges is necessary, so the filters last longer and require less changeouts

- Smaller footprints are possible because each unit handles more airflow

- Ships in as few pieces as possible for fast delivery

- Easy installation, operation and maintenance

- Built on 20 years of reliable field dust collection performance

- Gold Cone® X-Flo filter cartridge contains 375 square feet of media, offering the industry’s highest air-to-cloth ratio

The most important factor influencing collector sizing is the expected amount of dust/fume/smoke particulate being collected (the loading). Several things affect the loading. First is the amperage of the plasma cutter itself. A 300 Amp plasma will cut much faster and have a much higher loading than a 100 Amp plasma. Some tables may have two heads operating at the same time. Zoned tables have much higher loading due to the lower airflow for the amount of material being collected. It can be compared to source capture versus general ventilation on non-zoned tables.

• Smoke detector with fan shutoff and alarm

• Sprinkler system

• Spark Baffle

• Clean Sweep vacuum

LET US HELP YOU FIND A SOLUTION

GOLD SERIES X-FLO® PACKAGED (GSXP) SYSTEMS FOR PLASMA CUTTING TABLES

The Gold Series X-Flo Packaged is a plug and play dust and fume collection system that is ideal for plasma cutting applications where floor space is at a premium. The units are available in three sizes (2, 4 or 6 filter cartridges) and ship completely assembled and ready to plug in with features like a cam-lift dust drawer and a built-in air damper. All internal electrical connections, dust collector timer controls and fan controls are included, and accessories like fire detectors are factory-wired.

- Available in three sizes (2, 4 or 6 cartridges). All access to components (including controller, compressed air supply, access door, discharge drawer and integrated inlet damper) is on the front side of the collector for ease of use.

- Inlet damper is integrated into the collector as a standard feature. Damper is sized for appropriate airflow for the size/model.

- Discharge system features a 20-gallon drawer with sliding casters and a cam-operated lift device.

- Compact collector footprint with top-mounted fan saves space.

- Diaphragm valves are mounted low for maintenance accessibility.

- Fire sprinkler in the clean air plenum provides more effective fire suppression.

- Smoke detector sends a signal to the dust collector to shut off the fan if it detects smoke in the clean air plenum.

Americas

Americas