Traditional HVAC filters have to be replaced only a few times a year when they fill up. But that’s not the case with dust collector filters that are constantly bombarded with dust. All that dust would fill up traditional filters every few minutes, requiring constant replacement.

That’s why dust collector cartridge filters, which are a different shape, use different media (fabric) and are self-cleaning. Filters are arguably the most important aspect of dust collecting, so this blog answers some questions facility operators most frequently ask us.

What are cartridge filters and why are they used in dust collectors?

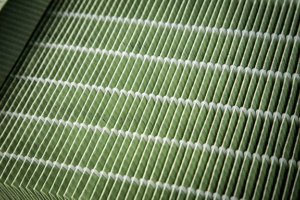

Cartridge filters are designed in a cylindrical shape so they can hold a lot more filter media than panel filters. This media traps the dust in the air as it flows through the dust collector. With cartridge filters, the media is pleated, so many more square feet can be packed into a filter. More square feet of media means more surface area available to capture more dust. Secondly, cartridge filters are designed to be self-cleaning, so dust collectors can continually process large volumes of dust without having to be turned off to change out the filters.

What is pressure drop, and how does it affect filters?

As dust collectors move huge volumes of dust-laden air through the system, the filter cartridges become loaded with dust particles. Clogged filters restrict airflow, which causes the dust collector’s fan to work much harder to keep the airflow high enough to capture the dust particles. This increases the static pressure, also referred to as pressure drop, which is measured by inches of water. When pressure drop is high, the dust collector has to consume much more energy to do its job. For this reason, the goal is to maintain a low pressure drop.

Pressure drop can only be reduced by replacing the filters or knocking the dust off them. Since industrial applications fill up the cartridges every few minutes or seconds, there needs to be a way to constantly knock the dust off. That is called the self-cleaning or pulse cleaning process.

How do self-cleaning filters work?

Dust collectors have internal cleaning systems that eject bursts of compressed air into the center of the filter cartridge every few seconds. These air pulses push through the filter media at high velocity (generally 90-100 psi), which blows most of the dust out of the cartridge, so it falls down into the hopper. This is known as pulse cleaning or jet pulse cleaning.

When a dust collector is initially set up, it can be programmed to clean at a specific time interval or each time pressure drop reaches a specific level

How long do filter cartridges last in a dust collector?

Since dust collector filters are continually pulse cleaned, they are less disposable than HVAC filters. They have a much longer life, and can last up to a year, despite processing constant high volumes of dust. Of course, filter life is highly dependent on the type of filter used, whether it is a standard-quality or premium-quality filter, and whether the correct media is used for the specific application.

Are there different ways of pleating filter media?

Yes. Most manufacturers pleat the media to pack as much as possible into each cartridge. This can be ineffective, however, if the pleats are so tight that the media is compressed instead of open to the airstream.

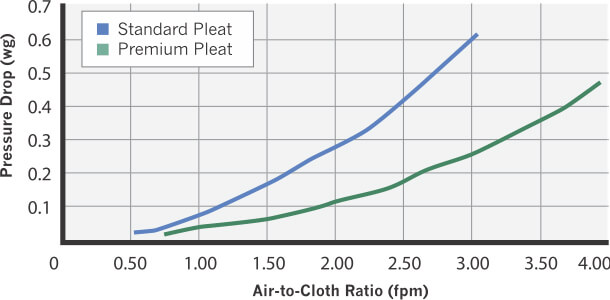

Camfil uses patented HemiPleat technology to solve this problem. We apply synthetic beads to the media to hold the pleats open so more media is available for dust capture. The result is filters that last longer because they pulse clean better. This pleating technology provides the lowest initial pressure drop and the lowest pressure drop through the lifetime of the filter.

The figure to the left shows that filters with this technology have a lower pressure drop for any given airflow that standard filters.

The figure to the left shows that filters with this technology have a lower pressure drop for any given airflow that standard filters.

Of course, we offer HemiPleat open pleating technology for all Camfil dust collectors, but we also make filter cartridges to fit most leading dust collector brands.

What is Gold Cone filter technology?

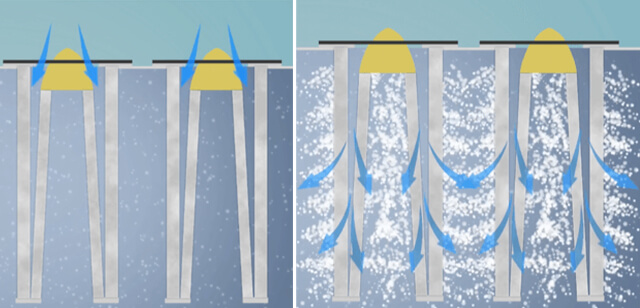

The Gold Cone filter design is patented by Camfil and is only available for Camfil brand dust collectors. With this design, an extra cone of packed HemiPleat filter media is inserted inside the cylindrical filter. This open-bottomed, inner cone of media greatly expands the usable surface area of cartridges.

The inner cone is configured so that pulsed air is evenly distributed top to bottom along the outer pack of the filter and down through the inner cone pack. With each pulse, Gold Cone filter cartridges eject more dust out of the collector than any other filter and help maintain a low pressure drop.

It is better to arrange filters vertically or horizontally in dust collectors?

Many companies design dust collectors with horizontal filters. This is the most common configuration, possibly to try to reduce the overall footprint of the collector. But this design can be problematic when the filters are pulse cleaned. When multiple horizontal filters are stacked above each other, the dust ejected from the top filters falls down onto the filters below.

Camfil takes a very different approach. We design our filters to be installed vertically to work with gravity. The filter cartridges hang side by side in the collector with their pleats facing out. With this configuration, the dust from all the filters falls straight down to the hopper when they are pulse cleaned. This offers a huge advantage over horizontal-style filters that pulse 90% of the dust back onto adjacent filters and only 10% into the hopper. With cartridges installed vertically, there is no reintroduction of dust from row to row, so filters last longer.

What type of filter media is best for my application?

A dust collector is only as strong as its filter cartridges, which makes filter selection vital. Filter cartridges need to use the type of media that is appropriate for your specific application and dust. For example, your application may require media treated with coatings that promote dust release, flame retardance or conductivity.

Using the wrong media causes high pressure drop and energy costs, while using the correct media creates a safer, cleaner work environment with less dust collector maintenance. Camfil offers filter media including:

- Green (standard) media for nuisance dusts

- Synthetic media for fibrous dusts

- Aluminized and carbon-treated media for statically charged dusts

- Hydro-oleophobic media for high-humidity applications

- Flame-retardant media for flammable or combustible dusts

What’s the best way to figure out which filter is best for each customer?

Since filters are so critical for dust collector performance, we start from scratch with every customer and make no assumptions based on previous filter specs. We ask multiple questions including what the filter is being used for and the previous filter’s lifespan. We also ask about the characteristics of the dusts that need to be collected. In some cases, we ask the customer to send a sample of their dust to our lab so we can test it. We do all of this to make sure Camfil recommends the filter that will perform best and last longest.

To learn more about dust collector filters, click here to listen to our podcast, All About Filters or visit our website by clicking this link.

Americas

Americas