Health and Emission Hazards of Dusts from Thermal Spray Processes

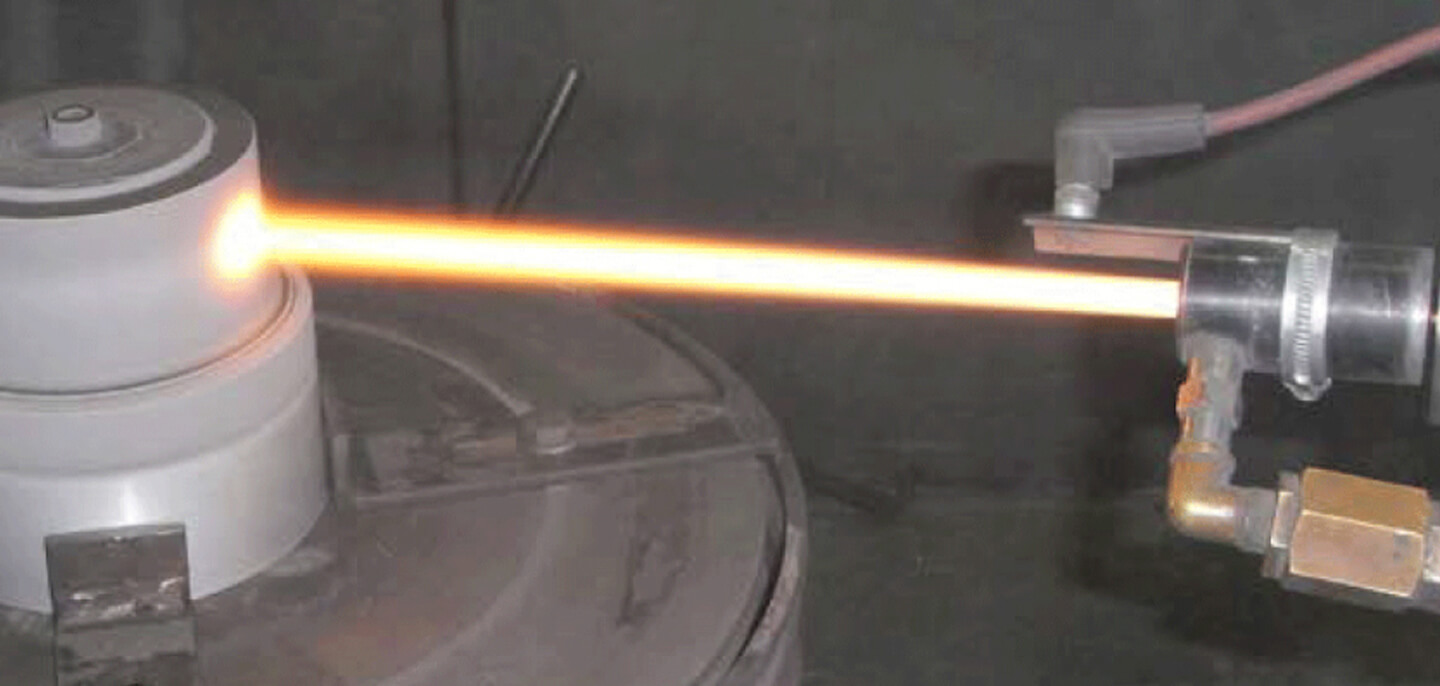

The thermal spray powder coating process atomizes molten metals, which can produce contaminants that threaten worker health and safety. The process creates airborne particles that can be smaller than one micron and can embed deep in lung tissues. Most commonly, metal dust particles enter the respiratory system, but they can also irritate the eyes, mouth, throat, stomach and skin.

The fine dust particles generated during powder spraying can contain a variety of metals associated with health risks. Some of the materials that are sprayed, like nickel and chromium, are known carcinogens. In fact, most chromium-bearing materials can produce hex chrome particles when exposed to the high energy levels required for thermal spraying. Other metals like zinc, bronze, cobalt, aluminum and copper alloys can cause sickness, fever, allergic reactions, lung fibrosis, skin diseases, or pneumoconiosis. Manufacturers must know the permissible exposure limit (PEL) for all materials they handle to stay compliant with OSHA regulations. Dust collectors are the preferred engineering control to maintain a safe PEL and safeguard operators from serious health concerns.

Combustible Dust Fire and Explosion Hazards

Metal particles in the air can create an explosion hazard. Dust collectors prevent combustible metal dust particles from accumulating on floors and other surfaces. However, it is crucial for dust collection systems that handle combustible dusts to be sized correctly for each spray application and according to the recommendations in a dust hazard analysis and NFPA 652. Dust collectors must also be fitted with the correct explosion protection equipment: explosion vents, flame retardant cartridges, and possibly spark traps. A correctly engineered dust collection system minimizes risks, protects workers and keeps manufacturers in compliance with OSHA regulations and NFPA standards. Camfil APC compliance experts are ready to help.

APPLICATIONS THAT CAN CREATE DANGEROUS DUST

- Electric arc wire (EAW) spraying

- Flame spray powder or wire

- Electric arc spraying

- High-velocity oxy-fuel (HVOF) and high-velocity air-fuel (HVAF)

- Plasma spraying

- Vacuum plasma spray

- Cold spray

Download the White paper today

This white paper reviews the hazards of airborne contaminants generated by thermal spray processes and describes how to design a dust collection system that minimizes risks and ensures regulatory compliance.

Learn this and more in the FREE White Paper

Resources and Literature:

GOLD SERIES X-FLO® INDUSTRIAL DUST COLLECTOR

The modular Gold Series X-Flo dust collector (GSX) was engineered to solve tough dust problems with a minimal footprint. It captures dangerous airborne metal dusts before they can be inhaled by operators or build up on shop surfaces. Camfil experts will work with you to understand your specific application requirements. Individual modules accommodate airflows up to 6,000 CFM each, providing a near-limitless variety of configurations that can be delivered in days instead of weeks. All GSX collectors feature heavy-duty carbon steel construction and thermal-cured powder coatings for unparalleled strength and durability.

It's crucial to gather the proper information when configuring a dust collector for thermal spray applications. There are many different types of processes and material coatings that will all react differently inside the dust collector. Camfil APC experts are familiar with design considerations like airflow, negative pressure, loading, emission, air-to-cloth ratio, and filtration required to solve the toughest dust problems. Thermal spray applications are generally sized at a conservative air-to-cloth (A/C) ratio with HemiPleat® fire retardant cartridges.

- Modular construction – easy to build and assemble in limitless sizes and configurations

- Tested to meet NFPA & ATEX standards

- Available with numerous explosion protection options

- Exceeds OSHA mandates for factory air quality

- Less pulsing of filter cartridges is necessary, so the filters last longer and require less changeouts

- Smaller footprints are possible because each unit handles more airflow

- Ships in as few pieces as possible for fast delivery

- Easy installation, operation and maintenance

- Built on 20 years of reliable field dust collection performance

- Gold Cone® X-Flo filter cartridge contains 375 square feet of media, offering the industry’s highest air-to-cloth ratio

LET US HELP YOU FIND A SOLUTION

Over the years, we tried several types of dust collection equipment on EAW spraying. However, all previous attempts at extended filter life (more than six months) failed until we installed a high efficiency "Farr Gold Series" cartridge collection system manufactured by Farr, Arkansas. At the time of this writing, the Farr Gold Series collector is still performing exceptionally well without a filter change after about a year and a half.

-David Drozd, Pamarco

Americas

Americas