In industrial facilities where heavy dust loads are a daily reality, operators face the persistent challenge of keeping dust collection systems performing efficiently without frequent filter changeouts and excessive energy costs. Inefficient filters with tightly packed media can restrict airflow, which often results in excessive filter costs and unplanned maintenance downtime. Both of these undermine productivity and drive up operating costs.

Selecting the right dust collector replacement filters is essential for maintaining consistent system efficiency, while also supporting emission control and protecting workers’ safety. Dust collector replacement filters designed with OmniPleat® technology from Camfil APC are engineered to meet these challenges head-on.

Read on to learn how replacement filters made with OmniPleat technology outperform conventional filters by extending service life and enhancing dust collector performance in demanding industrial environments.

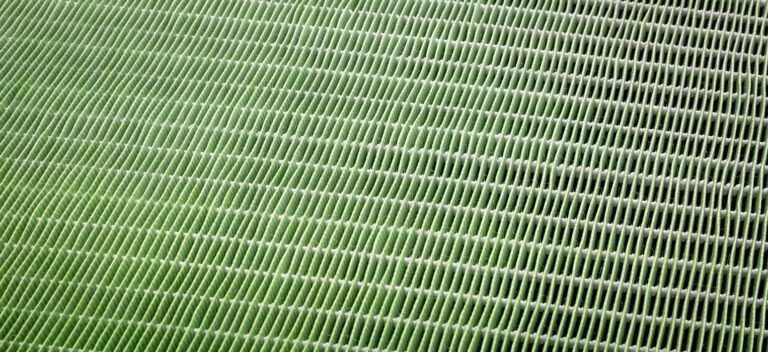

The Difference is in the Pleat Design

What makes OmniPleat technology unique is its proprietary pleat-forming system. Synthetic, custom-shaped glue beads are applied to both sides of the media pack to keep pleats wide open, evenly spaced and fully exposed to the airstream for maximum efficiency.

Pleat geometry is one of the biggest determinants of how a dust collector cartridge performs. Air doesn’t just pass through the media. It has to navigate the channels formed by the pleats. When those channels stay open, the airstream can contact more of the media’s surface area.

Why conventional pleats hit performance limits

Standard pleated cartridges often compress the media pack so tightly that a significant portion of the media surface is shielded from airflow thus limiting the surface area exposed to the airstream. This crowding increases resistance to airflow and pressure drop, making pulse cleaning less effective because dust is more likely to form between pleats and cling in narrow channels.

When filter media becomes loaded with dust, the fan has to work harder to pull air through the filter. This higher resistance shows up as a larger difference in air pressure between the dirty side and the clean side of the filter, known as pressure drop. As pressure drop increases, airflow through the dust collection system decreases unless more energy is used to compensate, which can reduce dust capture effectiveness.

The OmniPleat design uses glue-bead supports that shape and stabilize the pleat channels. By keeping pleats wide open and uniformly spaced, the design promotes complete media utilization, meaning the available filter media is fully exposed to airflow instead of being trapped in pinched pleat pockets.

How pleat design connects to key metrics

With more media effectively in play, filters with the OmniPleat design maintain airflow with less resistance, which delivers lower pressure drop and releases more dust during pulse cleaning. These factors reduce energy demand on the fan motor and help to cut air consumption tied to pulsing. In fact, filters manufactured with OmniPleat technology will last 30% longer than standard filters. The wide pleats also enable dust to be distributed more evenly and allow pulse cleaning to remove the built-up dust cake more consistently.

How HemiPleat® Technology Set the Stage for the Next Evolution in Filter Media

In 2002, Camfil APC reshaped the dust collection filter market with the introduction of HemiPleat® technology, a design developed to address tightly packed pleats that restrict airflow and waste usable media. Camfil APC engineers approached the problem from a structural standpoint and designed wide pleat spacing supported by synthetic beads applied to the media pack. These beads act as permanent separators that stabilize pleat geometry and prevent collapse under airflow and dust loading. By holding pleats open, the design ensures that the entire media surface is available for filtration rather than being trapped in compressed folds.

This structural change achieves more media utilization and produces significant dust collector performance gains. Filters built with HemiPleat technology reduce resistance to airflow, which helps to maintain system performance without requiring increased fan energy. Improved dust release during pulse cleaning also extends usable filter life, allowing facilities to reduce changeouts while maintaining collection efficiency. These outcomes positioned cartridges made with HemiPleat as longer-lasting alternatives to standard pleated filters in a wide range of industrial applications.

Market adoption reinforced the value of the design. Over time, HemiPleat technology became widely accepted across industries that demanded consistent airflow and predictable maintenance intervals. Its success validated the principle that pleat engineering is as important as filter media selection.

Building on this foundation, Camfil APC advanced the same core engineering concepts into OmniPleat technology. While HemiPleat established the benefits of wide, supported pleats, OmniPleat refined the approach with proprietary, custom-shaped glue beads applied to both sides of the media pack for pleat stability and airflow exposure. This evolution advanced a proven pleating technology through improved geometry, consistency and manufacturing precision.

Measurable Performance Gains With OmniPleat Media Packs

When dust collector replacement filters are manufactured with OmniPleat media packs, the impact on dust collector performance is realized almost immediately. Energy efficiency is another direct benefit related to pleat design. As noted above, the stabilized pleat geometry of the OmniPleat design reduces airflow restriction, resulting in lower pressure drop across the filter. Lower pressure drop reduces the workload on fan motors and helps decrease compressed air consumption during pulse cleaning. These performance benefits contribute to reduced system energy demand over time.

Pulse cleaning performance also improves when pleats remain fully exposed to the airstream. OmniPleat technology enables the media to release more dust during cleaning cycles because debris is less likely to bridge between pleats or lodge in narrow channels. This improved dust release allows filters to maintain consistent airflow longer between cleaning cycles.

Durability plays a critical role in demanding industrial environments. The reinforced pleat structure of OmniPleat technology resists collapse and abrasion caused by continuous pulsing and heavy dust loads, helping filters maintain their shape and performance throughout their service life.

Together, these performance gains allow facilities to extend service intervals, reduce system-related expenses and maintain dependable dust collection performance without sacrificing efficiency or reliability.

Media Options for Every Challenge

Filters manufactured with OmniPleat technology are designed to meet a wide range of industrial dust collection demands by offering multiple media options that align with specific operating conditions. Camfil APC produces dust collector replacement filters with OmniPleat technology in eight distinct media types, allowing facility managers to select performance characteristics that match their processes rather than relying on a one-size-fits-all solution.

For general dust collection needs, GR (Standard Green) media provides reliable filtration for common dry dust applications, while XG (eXtreme Green) builds on that foundation with enhanced durability for higher dust loads or more aggressive operating environments.

Applications involving combustible dust or elevated temperatures often require additional safeguards. FR (Flame Retardant) media is engineered to resist ignition, and XF (eXtreme Fire Retardant) extends that protection for harsher conditions. For environments where both fire resistance and static control are critical, FC (Flame Retardant Carbon Impregnated) and XFC (eXtreme Fire Retardant Carbon Impregnated) media incorporate carbon to help dissipate static charge.

For fine particulate capture or challenging chemical exposures, XS (eXtreme Synthetic) media offers increased strength and resistance to moisture, while FRPTFE (Flame Retardant PTFE) combines a membrane surface with flame-retardant properties to enhance surface filtration and dust release.

By pairing these specialized media options with OmniPleat’s advanced pleat geometry, Camfil APC enables operators to upgrade filter performance without modifying existing dust collection equipment. The result is a tailored filtration solution that aligns with application requirements while maintaining consistent airflow and dependable system operation across a wide range of industrial environments.

Ready to upgrade your dust collection system? Learn more at https://camfilapc.com/.

Americas

Americas