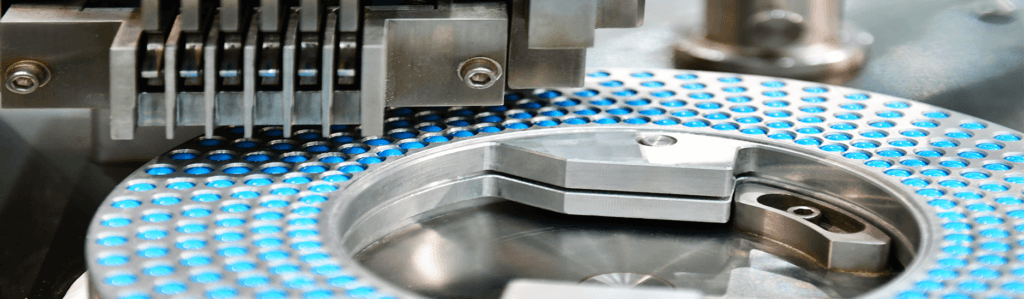

Many pharmaceutical companies consider the continuous solid dose manufacturing process an improvement over batch production. That’s because the continuous process simultaneously charges and discharges ingredients and finished product. Batch manufacturing, on the other hand, is a step-by-step process, and it can process only one batch at a time. And each step of the process requires its own piece of equipment.

Continuous manufacturing enables pharmaceutical manufacturers to use fewer pieces of equipment, work out of smaller facilities, simplify processes and have better product quality control. However, the benefits of continuous manufacturing can be achieved only if the auxiliary equipment is able to keep up.

Uninterrupted operation of the dust collection system is critical in continuous manufacturing operations because it needs to operate 24/7. Here are tips to help your dust collection system run effectively and efficiently around the clock to capture harmful dust generated from solid dose processing.

Keep Filters Clean

Dust collectors are able to run continuously when they effectively remove dust from their filters using reverse pulse cleaning. This type of cleaning system uses compressed air as needed to remove dust that is restricting the airflow and raising the dust collector’s differential pressure (dP). Nozzles direct pulses of compressed air to the interior of the filter cartridges to eject the dust from the outer surface of the media. Click here to watch a 1-minute educational video demonstrating pulse cleaning.

The most efficient way to operate a reverse pulse cleaning system is to use a controller that reads the dP across the filters, which is referred to as on-demand cleaning. That way, the cleaning system initiates automatically when the set dP is reached and returns it to a stable level.

The ejected dust is stored in a suitable receptacle where it can be emptied when necessary without having to shut down the dust collector. However, it is possible for the pulse cleaning process to cause pressure disturbances in the dirty air ducting and the process machine to which it is connected. That’s why it’s important to use proactive strategies to prevent these disturbances, such as:

- Reducing the compressed air pressure

- Using segmented filter designs

- Employing off-line cleaning regimes

- Installing automatic dampers

All of these solutions can be designed into the system to help prevent upstream pressure issues.

Maintain Energy Efficiency

In continuous manufacturing, energy efficiency is a primary consideration for the design of all ancillary equipment, including the dust collectors. Dust collectors consume energy in two main areas: the fan and the pulse cleaning system. The fan produces the negative pressure to draw in dust and air from the process equipment and remove the dust that is generated. Correctly designed dust collection systems with well-balanced ducting minimize the fan’s power consumption. Using variable-frequency drives and high-efficiency motors will also reduce energy consumption significantly.

The second main area of energy consumption is the filter cleaning system. Compressed air is expensive to generate, so the more efficient the filter cleaning process, the lower the average dP and compressed air consumption will be. Therefore, it is important to consider the following when selecting the most energy-efficient dust collector for the application:

- Dust release characteristics of the filter media

- Filter cartridge design

- Type of pulse cleaning mechanism

Select a Fully Integrated Dust Collector

As manufacturing processes demand smaller process machines and less floor space, the same stipulations are placed on the ancillary equipment. This includes the dust collectors and the cartridge-style filters that are typically used for dry dust applications. Cartridge-style filters have a greater surface area and smaller footprint than bag filters. In addition, dust collectors typically need to incorporate a HEPA filter section and a fan, which can take up valuable space in the production floor or suite. Using a fully integrated compact dust collector is a space-saving strategy that is sometimes a necessity. A more compact unit can also have much lower installation costs.

Incorporate Safety Features

Every continuous manufacturing process is evaluated before implementation to determine the potential health and safety risks. With dust collection, the main risks involve potential worker exposure to harmful dusts and a fire or dust explosion from combustible dust.

A well-designed and maintained dust extraction system removes the airborne dust from the workplace, reduces worker exposure and prevents cross-contamination of other products.

However, workers can also be exposed to the harmful dusts when they remove the collected dust during filter changes and when doing maintenance work. Containment systems can be used to limit worker exposures and reduce cross-contamination during these procedures. Dust collector containment systems vary in design, so it is good practice to use a system that has been surrogate tested and validated by an independent organization. It is also important to get safe-change systems that are ergonomically designed and easy to use so that the maintenance teams do not have any issues following the procedures.

Fire and explosion risks can be managed effectively if the facility personnel fully understand the process, ingredients and other materials being processed. Dust explosion characteristics are known for many products used in pharmaceutical manufacturing processes. This information is required under current National Fire Protection Association (NFPA) standards, even for proprietary products. The pharmaceutical manufacturer is required to complete explosivity testing, then provide the results to equipment suppliers in order to correctly design their systems.

When this information is not available, values such as the Kst (rate of explosion), Pmax (maximum explosion pressure) and MIE (minimum ignition energy) can be determined by contracting a specialist lab to conduct explosion tests. This information is necessary to select the most appropriate explosion protection equipment and apply it to the dust collector to ensure compliance with NFPA standards.

For processes with smaller air volumes, it is sometimes possible to avoid specifying expensive explosion protection equipment by selecting an advanced dust collection system that has documented performance-based testing showing that it can safely contain dust explosions. The cost savings can be significant with compact dust collectors, particularly with respect to installation and ongoing maintenance costs.

Partner with an Experienced Equipment Supplier

Dependability is a critical requirement when selecting machinery for continuous pharmaceutical applications. Dust collection suppliers should destructively test their equipment to provide real-world performance data that can be used to determine the equipment design and explosion protection requirements.

In addition, the dust collector supplier must also be able to provide dedicated sales and after-sales support service to ensure the availability of parts, so the processes can continue with minimal downtime. Dust collector maintenance must also be as quick and simple as possible to avoid unnecessary production delays. Reliability applies to both the equipment itself and the people responsible for the project at each stage. A well-established company with a customer-focused approach will be a more reliable partner.

If you have questions about dust collection systems for solid dose pharmaceutical manufacturing, contact our experts.

Americas

Americas