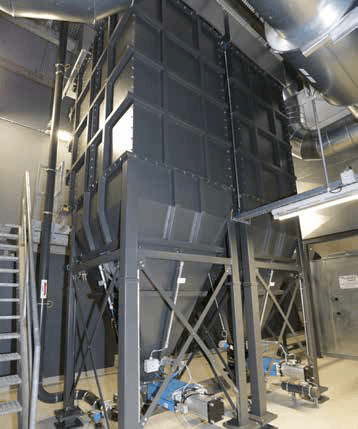

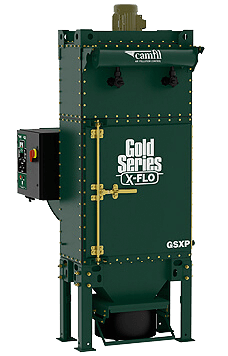

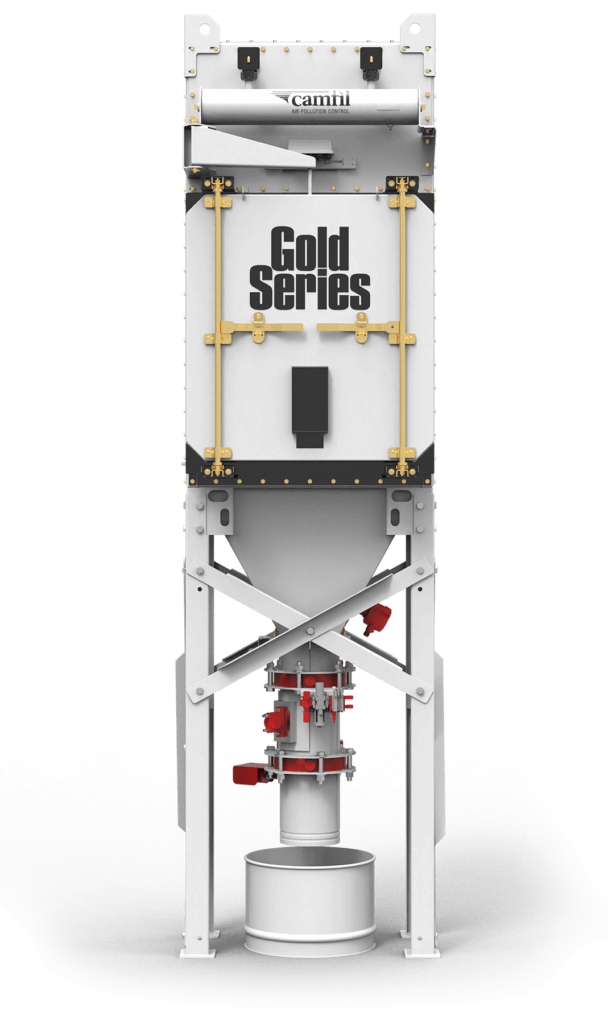

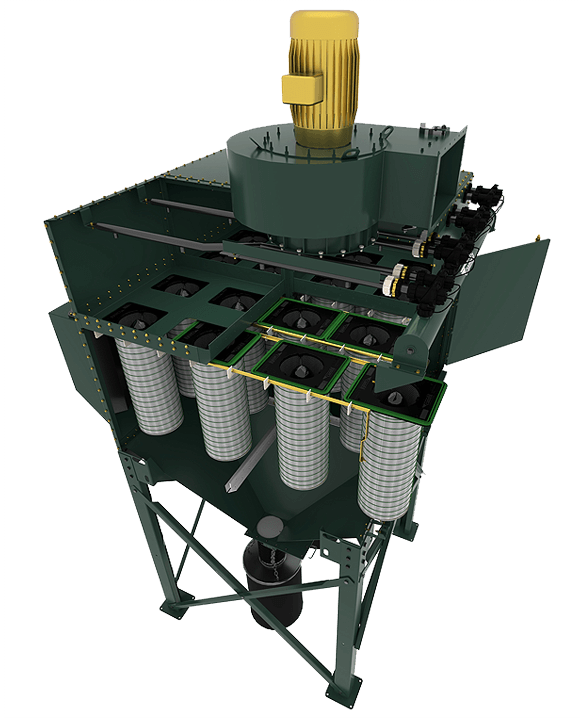

Auto Body Parts Processed with Clear Lungs in Gold Series Booths

Challenge Ogihara America Corporation is a manufacturer/supplier of automotive body parts for Mercedes-Benz. The sanding and grinding operations in this plant caused a dust cloud that drifted across the whole plant, settled on the floor (and everything else) and was swept up daily. Without a dedicated dust collection system in place, workers wore respirators for safety. However, when the air...

Americas

Americas