Dust Collectors That Accommodate Your Needs - Cabinetec

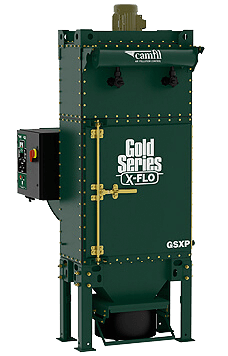

Challenge Cabinetec is a manufacturer of quality framed and frameless box cabinetry. This large operation produces cabinetry in ten different wood species, which generated a substantial amount of wood dust in the air. But Cabinetec had a limited amount of room for a dust collection system that could handle their operation. Solution GS96 on a wood application at Cabinetec in St. George,...

Americas

Americas