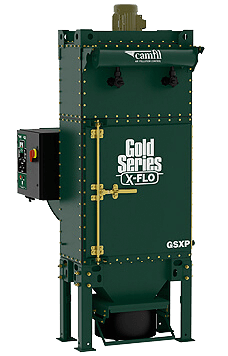

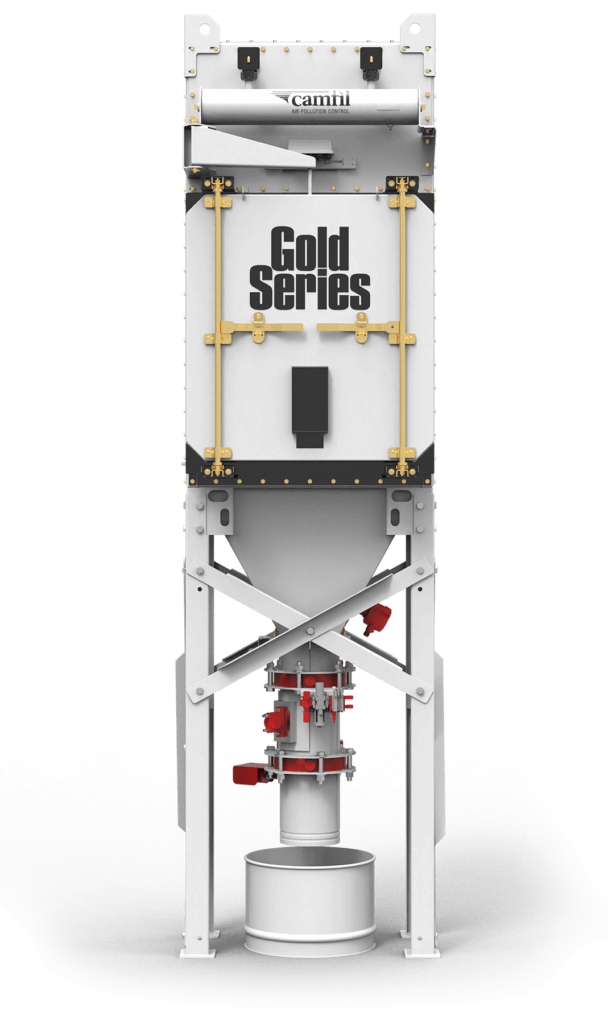

Gold Series® Finds a Home in Blasting Application

Challenge A government-affiliated agency needed a unit for a blasting operation that lacked a dust collector. The blasting application consists of blasting plastics, sponge rubber, and garnet with grit. The agency’s maintenance department initially made contact with Camfil APC through a trade magazine. GS96 Cartridge Access Door Platform Solution Scot Soncrant, Camfil APC sales representative for Air Improvement Resources, Inc.,...

Americas

Americas