Dust collectors are important safety tools for your facility. However, it is really important that your dust collectors are designed, installed and maintained properly. If not, they might not be providing the indoor air quality required for safety. Or worse yet, the dust collector itself can be a combustible dust hazard if it doesn't have the correct explosion protection.

Fortunately, there are easy-to-spot clues that can help you identify if your collector is not operating optimally. We’ve compiled a few of the most common warning signs of an unsafe dust collector and what you can do to address these issues.

1. Improper Vent Design

If your operations produce combustible dust, the National Fire Protection Association (NFPA) requires you to equip your dust collector with deflagration protection. Vents and flameless vents are common, cost-effective methods to help keep your facility and workers safe in the event of a dust collector explosion.

It is essential to understand the pressure capabilities of your dust collector to choose the correct vent size for your system. The venting vessel must be strong enough to handle the vent’s deflagration and burst pressure. The enclosure is designed to be stronger than the burst pressure of the event. This ensures that the deflagration is relieved of pressure before it can build to levels that would destroy the collector enclosure.

2. Unprotected Ductwork

In addition to deflagration vents, the NFPA also requires that facilities protect the ductwork and safety processes upstream of the dust collectors. That means equipping the ducting with dampers and isolation valves designed to minimize the risk of deflagration within these components.

Adding a flow-activated inlet isolation valve helps to protect upstream work areas when deflagration occurs in a dust collector. During deflagration, the pressure wave closes the valve preventing the passage of flame and smoke to areas upstream of the valve. The valve latches shut and must be opened manually. The NFPA requires that the ductwork between the dust collector and isolation valve be designed to withstand two times the reduced pressure reached following the venting of the dust collector.

3. Overfilled Hoppers

The hopper is designed to funnel dust to a storage bin. Never store dust in the dust collector’s hopper. Dust that has accumulated in a hopper creates a significant risk for fire and deflagration. It may also diminish the collector’s performance by clogging the system and preventing the pulse cleaning from performing optimally.

Self-dumping hoppers provide easy dust disposal while protecting against unwanted dust leakage. When the hopper is full, detach it from the bottom of the collector, lift the hopper onto a fork truck and pull a lever to swing the lid open and dump the contents into a larger disposal container. Self-dumping hoppers can be used for a range of dry dusts, including those that must be reclaimed or recycled after the collection process.

4. Inefficient Filters

A simple but important safety rule is to change out dust collector filters before they become laden with dust to maximize the efficiency of the collector and minimize worker exposure. Replace the filter if you notice:

- Airflow through the system has reached the differential pressure limit prescribed by the manufacturer.

- Pressure drop across the collector is negatively affecting the ability of the dust collection system to capture dust.

- Dust escapes the filter into the facility.

Some long-life cartridge filters can operate for two years or more between change-outs. However, heavy dust-loading applications generally require more frequent filter replacements.

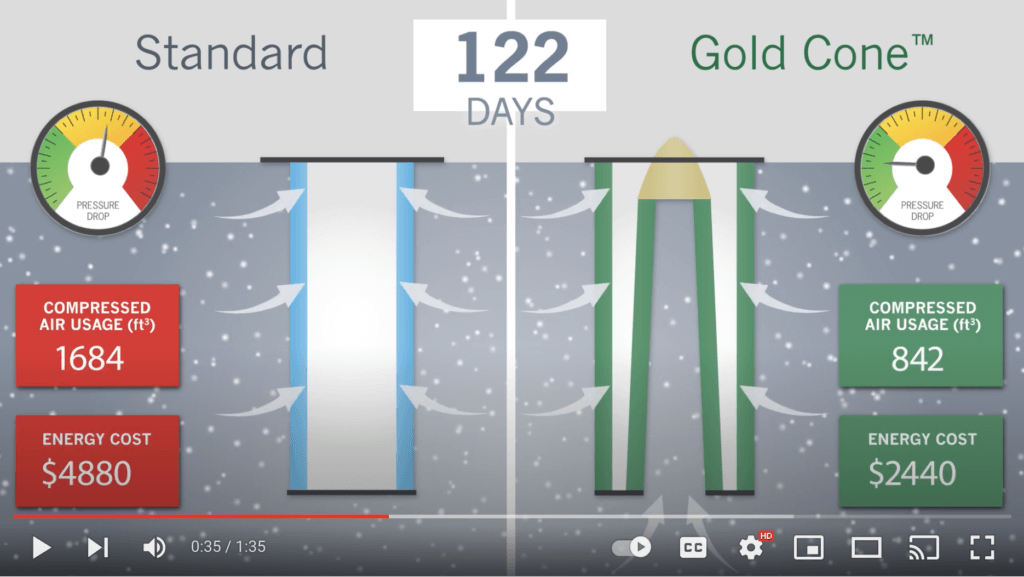

Watch this video comparing the change-out time for different filter cartridges.

5. Cumbersome Filter Change-Outs

Ideally, your workers should never have to enter the dust collector to change filters. Dust collectors that require entry during service put workers at risk and require companies to file confined space entry permits and monitor for gas. For that reason, many cartridge-style dust collectors offer easy filter change-outs.

Cartridge dust collector filters are designed to slide in and out of the housing with ease. Look for a machine that has quick-open, heavy-gauge doors that are fully reversible for accessfrom either side and have a lock-out feature for worker safety. In addition, vertically mounted filters help to make both the pulse cleaning and change-out process easy and efficient.

Final Thoughts

Keeping your dust collector operating safely and efficiently is a necessary task to ensure worker safety and facility compliance. Carefully monitoring your dust collection system for these warning signs is a crucial step to maintaining a safe facility. To learn more ways to keep your dust collection system operating at its best, download our eBook, 10 Ways to Keep Your Dust Collector Operating Safely.

Americas

Americas