There are many brands on the market and options to consider when purchasing new filter cartridges for your dust collection systems. Many filter manufacturers claim their products cost less than competing brands. Others claim they work better and last longer. However, without understanding how filter cartridges differ, it can be difficult to decide what’s best for your application.

With that in mind, we’ve listed the three main competitive advantages of Camfil Gold Cone™ dust collector filters and explained how they differ from standard filters and competing filter technologies

More Effective Pulse Cleaning

Effective pulse cleaning is critical to ensure your dust collection system runs continually at its optimal performance. Here’s why. As a dust collector runs, dust loads onto its filter cartridges, “blocking” the airstream. The resistance caused by dust-laden filters increases the differential pressure in the system and causes it to work much harder to maintain the required airflow. Left unchecked, the dust collector would not be able to sustain the CFM required to maintain its dust-collecting performance.

The pulse cleaning system is what continually removes the dust from the filters to maintain the required airstream and pressure drop. When it senses the pressure has reached a certain level, the system blasts compressed air down through the center of the filter, expelling the excess dust. But some filter cartridges release a lot more of the trapped dust than others with each pulse because of their shape and the way their media is pleated. Click here to learn more about pulse cleaning.

Gold Cone filters use proprietary HemiPleat® pleating technology that stays cleaner and lasts longer than traditional filters. Synthetic beads hold the pleats open and keep them evenly spaced, which greatly expands the usable surface area of each filter cartridge. This means more dust can be loaded onto each cartridge during use and then released when pulse cleaned. Additionally, each Gold Cone filter contains 375 square feet of usable media, offering the industry’s highest air-to-cloth ratio.

Use Less Compressed Air and Energy

As explained above, when filter cartridges are packed with dust, they have to work harder and use more compressed air for pulse cleaning. Producing compressed air is expensive and can be the least efficient use of energy in a plant.

Since Gold Cone filters require less frequent pulse cleaning, they use less compressed air than standard filters. They can maintain lower pressure for longer periods of time, so they use up to 70% less compressed air and 50% less energy than standard filters.

Gold Cone filters are designed to be placed vertically inside the dust collector. This design enables dust to be ejected from the top to the bottom of the filter cartridges. With each pulse, more dust is ejected and falls directly into the hopper instead of onto other filter cartridges, which happens with filters that are installed horizontally. Keeping cartridges as free from dust as possible is the key to keeping a dust collector performing optimally for a longer period of time.

Last Twice as Long

No matter how well filter cartridges are designed, they will eventually get loaded to the point that the system can’t maintain the required airflow and pressure drop despite frequent blasts of compressed air. At that point they must be replaced. This happens with every dust collector, but Gold Cone filters require change-out far less frequently than standard filters because of their proprietary design and pleating technology.

Changing filter cartridges less often not only reduces purchase costs, it reduces the downtime and maintenance spent on change-outs as well as the costs to safely dispose of the cartridges. If you are collecting toxic materials, disposal costs can be quite high.

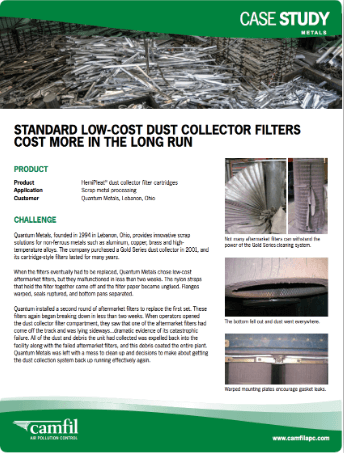

Additionally, the powerful burst of air emitted during pulse cleaning is hard on filters. Some standard filters have even been reported to break apart after just one pulse. Gold Cone filters are made from a durable blend of fibers and then treated with protective coatings relevant to your facility’s dust type in order to withstand elements like moisture, flame or static.

Gold Cone filters constructed with the correct filter media for your application will maximize airflow while minimizing filter change-outs, compressed air usage and energy costs.

We created a filter comparison video to show how Camfil Gold Cone filters perform over a year’s time versus standard dust collector filters. See how pressure drop, compressed air usage and energy costs vary as days pass.

The experts at Camfil APC will work with you to help you determine the best filter and filter media for your specific dust type. We can help you understand your dust and choose the right filter that will perform better, use less energy and last longer because it was chosen with your application in mind.

Americas

Americas