The National Fire Protection Association (NFPA) is a U.S.-based international nonprofit organization that develops consensus-based fire and life safety standards. Developing its fire safety standards since 1896, NFPA publishes hundreds of codes and standards covering everything from building fire codes to electrical safety and industrial hazards. These standards are widely used as benchmarks to minimize the risk and impact of fires, explosions and related dangers in various industries. One critical area NFPA addresses is combustible dust safety because of the severe fire and explosion hazards these fine particles pose in industrial settings.[1]

Recently, the NFPA introduced NFPA 660: Standard for Combustible Dusts and Particulate Solids, a safety standard designed to address the hazards of combustible dust. Officially released effective December 6, 2024, NFPA 660 consolidates multiple NFPA dust-related standards into a single comprehensive document. This unification simplifies compliance and provides a clearer, more cohesive approach to managing combustible dust risks across industries.[2]

Read further to learn what NFPA 660 entails and what it means for facility operators and personnel. This article covers why NFPA 660 was formed, its key requirements and changes, and strategies for compliance. By understanding NFPA 660, you can better protect your facility and workforce from dust explosion hazards.

What is NFPA 660?

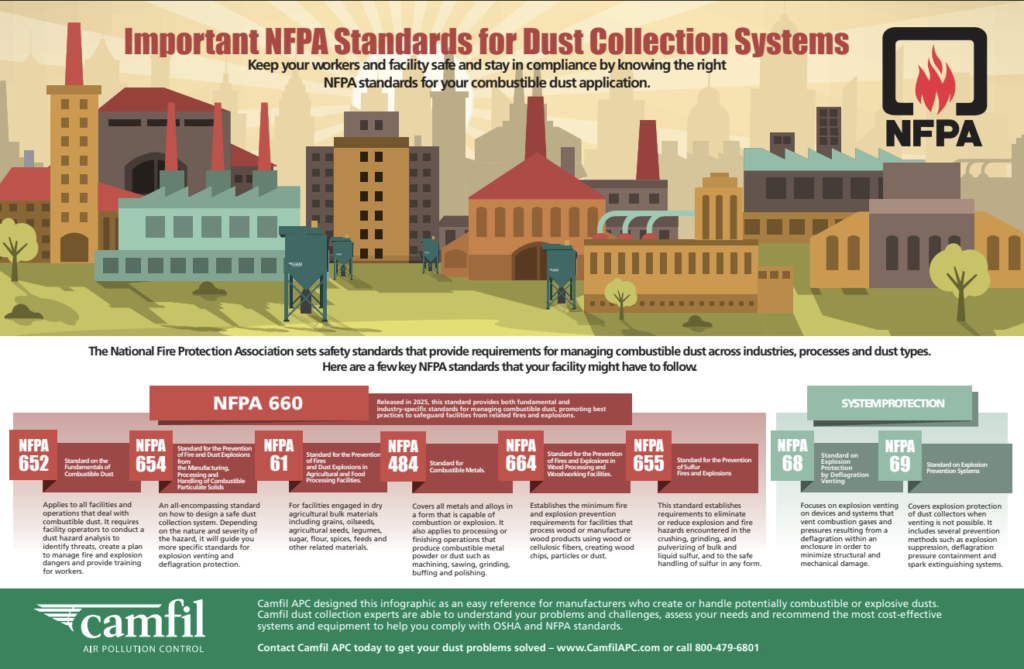

Prior to the release of NFPA 660, managing combustible dust safety meant navigating a patchwork of standards—NFPA 652 for general requirements, along with five separate standards tailored to specific industries or materials. To streamline this fragmented approach, the NFPA Standards Council approved a consolidation effort, resulting in NFPA 660: a unified standard that brings these various documents together under one framework. It’s important to note that NFPA 660 is a living document; therefore, expect updates and additions.

NFPA 660 incorporates the following standards that outline how to manage dust-related fire and explosion hazards:[3]

- NFPA 61: Standard for the Prevention of Fires and Dust Explosions in Agricultural and Feed Processing Facilities

- NFPA 484: Standard for Combustible Metals

- NFPA 652: Standard Fundamentals of Combustible Dust

- NFPA 654: Standard for the Prevention of Fire and Dust Explosions from Manufacturing, Processing and Handling of Combustible Particulate Solids

- NFPA 655: Standard for Prevention of Sulfur Fires and Explosions

- NFPA 664: Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

These standards will be retired upon NFPA’s final publication, and the new standard retains relevant content from each.

It is important to note that the following standards are not included in NFPA 660.

- NFPA 68: Standard on Explosion Protection by Deflagration Venting

- NFPA 69: Standard on Explosion Prevention Systems

- NFPA 499: Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

Structure of NFPA 660

The new standard is organized into chapters that first cover general fundamentals and then provide industry-specific requirements. It introduces a comprehensive framework for managing combustible dust hazards, building upon and refining the guidance found in previous standards.[4]

The letters in parentheses after each Annex title indicate which NFPA technical committee or subcommittee was responsible for developing or contributing to that specific Annex content. CMD stands for Combustible Metals and Dusts (the overarching committee or project). The suffix refers to the specific industry or materials within the scope of combustible dust hazards:

- CMD-FUN: Foundries––deals with dust hazards in foundries and similar industrial facilities.

- CMD-AGR: Agricultural and Food Processing––focuses on dust issues in agriculture, food and related industries.

- CMD-CMM: Combustible Metals Manufacturing––includes hazards related to magnesium, titanium, zirconium, etc.

- CMD-HAP: Hazardous Areas Protection––emphasizes explosion protection, spark detection and related topics.

- CMD-WOO: Woodworking––specifies dust hazards in woodworking facilities.

The document structure follows:

[1] https://www.nfpa.org/news-blogs-and-articles/Blogs/2024/11/06/history-of-nfpa

[2] https://www.nfpa.org/codes-and-standards/nfpa-660-standard-development/660

[3] https://camfilapc.com/blog/new-nfpa-standard-to-serve-as-single-source-on-combustible-dust-protocols/

[4] https://www.nfpa.org/codes-and-standards/nfpa-660-standard-development/660

Implementation Timeline

Facilities operators should become familiar with the new standard immediately. New facilities or major renovations should be designed according to NFPA 660. The post-publication transition period will likely grant a grace period to existing facilities to transition from the phased-out individual standards to NFPA 660.

Relationship to Other Standards, Codes and Regulations

NFPA 660 is designed to unify and streamline combustible dust safety practices, and its relationship with OSHA and regulatory bodies plays a critical role in guiding enforcement, compliance and risk management efforts.

Under the General Duty Clause (Section 5(a)(1)) of the OSH Act, employers must provide a workplace free from recognized hazards.[1] OSHA can cite facilities for combustible dust hazards under this clause, and NFPA 660 will serve as a unified benchmark. Also, OSHA’s Combustible Dust National Emphasis Program (NEP)[2] often uses NFPA standards during inspections and enforcement actions.

The International Fire Code (IFC)[3] and International Building Code (IBC)[4] use NFPA standards for combustible dust hazards. In addition, insurance providers may also require compliance with NFPA standards, including NFPA 660, as part of risk underwriting or loss prevention criteria.

Key Requirements and Changes in NFPA 660

Dust Hazard Analysis Requirements

Dust hazard analysis (DHA) guidance in NFPA 660 is more centralized and streamlined, reducing redundancies across industries. The new standard continues the NFPA 652 requirement for DHAs at facilities handling or generating combustible dust. NFPA 652 required DHAs by 2020, and NFPA 660 is expected to keep the five-year revalidation cycle.

Combustible Dust Hazard Identification

NFPA 660 emphasizes a comprehensive dust testing procedure that determines Kst (dust deflagration index), Pmax (maximum explosion pressure), MEC (minimum explosive concentration), MIE (minimum ignition energy) and MIT (minimum ignition temperature). It also provides clear expectations on when and how to conduct sampling and testing as well as better alignment on test requirements across industries.

Clarified Definitions and Terminology

Providing clearer scope and applicability, NFPA 660 unifies definitions across all dust types (metal, wood, agricultural, etc.). This measure is designed to reduce disputes during enforcement or audits.

Management Systems and Documentation

In chapter 10, NFPA 660 places a stronger focus on ongoing program management, not just one-time compliance. This includes requirements for written dust hazard management programs, employee training, and documentation of inspections, maintenance and corrective actions.

Housekeeping and Fugitive Dust Control

While continuing to reinforce the importance of minimizing dust accumulation on overhead surfaces and setting thresholds for action, NFPA 660 also places a new emphasis on risk-based housekeeping plans.

Interim Measures

Under NFPA 660, facilities must implement interim safeguards when full compliance cannot be immediately achieved. This requirement is designed to prevent last-minute safety upgrades and a rush to implement controls, which can lead to mistakes, shortcuts or noncompliance.

Industry-Specific Applications

After addressing universal fundamentals, NFPA 660 presents specific chapters tailored to different industries and dust types. This structure makes it easy to locate both the overarching guidelines and the extra rules that relate directly to your field. For example, NFPA 660 includes dedicated chapters for:

Agricultural and Food Processing

Chapter 21 of NFPA 660 consolidates and updates the content previously found in NFPA 61. Grain handling facilities face unique risks due to the volume and type of dust generated during processing, transfer and storage. NFPA 660 emphasizes the need for effective housekeeping, ignition source control and equipment design to prevent dust explosions. It also highlights the importance of managing fugitive dust in bucket elevators, silos and conveyors.

Agricultural facilities affected:

- Grain elevators

- Feed mills

- Flour mills

- Rice processing plants

- Oilseed crushing facilities

- Dry corn or soybean processing plants

As in NFPA 61, NFPA 660 requires agricultural and food processing facilities to align with the most recently updated DHA methodology and prevention strategies to ensure compliance and enhance safety.

Combustible Metals

Chapter 22 integrates NFPA 484 into NFPA 660 to address safety protocols for handling metal dusts, such as aluminum and magnesium, streamlining and enhancing guidelines for industries involved in metal processing.

This section outlines specific preventive measures for handling metal dust, including dust collection systems, using inert gases to reduce combustion risk and regular housekeeping.

Metal processing operations affected:

- Grinding and polishing

- Cutting and milling

- Additive manufacturing (3D printing)

- Welding and soldering

Sulfur

Chapter 23 updates NFPA 655 and specifically addresses the processing and handling of solid and molten sulfur, streamlining and enhancing safety protocols for industries handling sulfur. It covers hazard identification and risk assessment, safety management systems, engineering controls and preventive measures, and emergency planning and response.

Operations affected:

- Sulfur milling and grinding

- Sulfur storage and handling

- Sulfur packaging

Wood Processing and Woodworking Facilities

Chapter 24 of NFPA 660 specifically aims to provide a consistent and comprehensive approach to managing wood-dust-related combustible dust hazards across various woodworking industries, integrating the earlier NFPA 664 standard.

Examples of operations affected:

- Sawmills

- Furniture manufacturing

- Cabinet making

- Wooden flooring production

Combustible Dusts and Particulate Solids Not Otherwise Specified

Chapter 25 of NFPA 660 covers the foundational safety principles for all industries handling combustible dust. It is the go-to section for industries not addressed in the other sections of the standard—like chemical and pharmaceutical processing. Using NFPA 654 as its foundation, this chapter delivers clear guidance on how to identify and assess combustible dust hazards specific to your operations handling powders, particulates or fine solids.

It emphasizes the importance of implementing strong engineering controls like dust collection systems and explosion venting. It also reinforces the critical role of employee training, regular maintenance and good housekeeping to keep operations safe.

Compliance and Implementation Strategies

Implementing NFPA 660 may seem daunting at first, especially if your facility operators were previously unfamiliar with some of the NFPA dust standards. However, with a systematic approach, you can achieve compliance. Here are a few best practices for adopting NFPA 660’s requirements and overcoming common compliance challenges.

Build Awareness

Both safety managers and engineering staff must become familiar with how the standard is organized and what it covers. You can access NFPA 660 for free online, through NFPA LiNK® or in print.[5] Focus on the sections most relevant to your operations. Training opportunities, such as seminars and webinars specific to NFPA 660, can be valuable tools for getting your team up to speed. Also, be sure leadership is informed that NFPA 660 now serves as the core standard for combustible dust safety to secure the support and resources needed to move forward.

Conduct a Gap Analysis

This assessment process compares your current dust safety programs and equipment against NFPA 660 requirements. Include the following in your gap analysis:

- Review your most recent DHA and check if it was performed more than five years ago. If it is older than five years, make conducting a DHA a priority.

- Evaluate your engineering controls to ensure that dust collectors, ducts and related processes are equipped with appropriate explosion protection measures, such as vents or suppression systems. Verify that all components are properly bonded and grounded in accordance with NFPA 660, NFPA 68 and NFPA 69 standards. Identify any equipment lacking necessary safeguards—for example, the absence of explosion isolation on extended duct runs or filter receivers without venting—and prioritize these areas for upgrades to enhance safety and compliance.

- Regularly review and document cleaning schedules and procedures to ensure they meet NFPA 660 requirements defining specific design criteria for equipment handling combustible dust.

- Evaluate maintenance and training programs according to the requirements outlined in NFPA 660, including inspections, emergency preparedness, incident investigation and management of change. Also maintain thorough documentation of periodic inspections for dust safety systems, as mandated by NFPA 660.

- For operations involving metal dust or other unique cases, conduct specialized hazard evaluations, as required by NFPA 660. The standard introduces new processes to evaluate self-heating, thermal instability, water reactivity and chemical reactivity hazards.

By systematically aligning each aspect of your operations with NFPA 660 guidelines, you can accurately identify areas needing improvement and ensure a safer working environment.

Prioritize Actions Based on Risk

Expect to find gaps between your dust safety program and NFPA 660. Not every issue can be resolved overnight, so take a strategic, risk-based approach. Tackle the most serious hazards first. For instance, if your DHA reveals excessive dust buildup in critical areas or a dust collector lacking explosion venting, take swift action because those are urgent concerns––even if it means shutting down for cleaning, adding venting or implementing other immediate fixes. You can address lower-priority items, like minor documentation gaps, over time.

Implement Engineering Controls and Upgrades

For any gaps identified in engineering controls, plan and execute the necessary upgrades. Here are some examples:

- Ventilation and dust collection improvements: Make sure your dust collection system, including hoods, pickup points and/or central collectors, is doing its job at the source, preventing dust from escaping into the workspace. Install additional local exhaust systems, if your NFPA 660 review shows a need for them. Also, verify your dust collector’s air recirculation compliance. NFPA 660 references industrial hygiene exposure limits for recirculating filtered air back into buildings. If you’re returning filtered air into the facility, your filters need to be highly efficient. In many cases, this means using HEPA secondary filters or installing systems that continuously monitor for leaks to ensure dust levels in the recirculated air stay within safe limits.

- Static mitigation: Static electricity is dangerous in facilities that handle combustible dust because it can act as an ignition source, triggering a dust explosion or fire. Install bonding wires or substitute nonconductive components where necessary to maintain proper grounding of all equipment. If you find that any flexible connectors are not anti-static rated, replace them with ones that comply with the required resistance specifications.

Improve Administrative Controls

Develop or update your written programs for combustible dust management to align with NFPA 660 requirements.

- Dust Hazard Analysis documentation: When conducting a DHA, be sure to document it in detail and treat it as a living resource that managers regularly consult. Develop a list of action items based on the assessment and actively follow up to ensure each one is completed.

- Housekeeping plan: Document the cleaning routine, including daily or weekly tasks, who is responsible for them, the cleaning methods to be used and acceptable conditions (such as a maximum dust thickness). Keep track of cleanings with a simple system—like a checklist that a supervisor signs off on after inspections. This supports compliance efforts and helps to make sure the work gets done consistently.

- Preventive maintenance schedule: Include dust safety equipment in your maintenance schedule. Keep records of these inspections.

- Training records: Develop training materials that introduce new employees to the fundamentals of combustible dust safety. For current staff, schedule an annual safety meeting to go over dust-related risks, review recent incidents and highlight any updates or changes. Keep a record of who attended and what was discussed. Make it clear that NFPA 660 is now the primary combustible dust standard and reinforce your facility’s commitment to safety best practices.

- Hot work and permit systems: Make sure to have a formal permit system in place for any hot work—like welding or grinding—conducted in areas where combustible dust is present. NFPA 660 requires that no hot work is performed unless the area has been properly cleaned and key safety measures, such as fire watches, are in place. If you don’t already have a permit process, implement one to enforce these precautions and ensure that personnel are following best practices.

Engage Experts and Resources

Combustible dust compliance can be complex, but you don’t have to do it alone. Consider consulting experts who specialize in dust safety.

- Equipment suppliers: At Camfil APC, our experts stay up to date with all NFPA and other industry codes relevant to combustible dust and indoor air quality standards, regulations and best practices to ensure compliance.

- Safety consultants: Fire protection engineering firms can perform DHAs and develop training programs.

- Insurance carriers: Certain insurance providers offer site visits by industrial hygienists or safety engineers because it’s in their best interest to help minimize potential losses. These professionals can identify combustible dust hazards you may have missed and recommend enhancements that align with NFPA 660 standards.

- NFPA resources: Consult the Annexes of the NFPA 660 standard, visit NFPA LiNK® and join the NFPA Xchange Community.[6]

Overcoming Common Challenges

Here are a few challenges facility operators might face when implementing NFPA 660 and strategies to handle them:

- Cost and budget constraints: Investing in safer equipment can come with a high price tag, which may make leadership reluctant. To build your case, emphasize the risks of inaction—devastating explosions can lead to loss of life, steep penalties and major financial damage. Stress that NFPA 660 is likely to be adopted into fire codes. In many cases, upgrades can be implemented gradually to manage expenses. Explore opportunities for insurance discounts or incentives tied to improved safety measures, which can help offset the investment. Ultimately, the cost of prevention is far less than the fallout from a serious incident.

- Technical complexity: Smaller companies without in-house engineers may find it challenging to handle tasks like vent sizing or conducting a DHA. In these situations, it’s smart to bring in external experts. The good news is that NFPA 660 consolidates previous standards, making compliance more straightforward—you now have a single, primary standard to follow.

- Ongoing monitoring and compliance: Once you’ve achieved initial compliance, the real test is maintaining it over time. Assign specific responsibilities to individuals. To keep dust safety top of mind, integrate it into your regular safety meetings or continuous improvement initiatives, ensuring it remains a consistent part of your overall safety strategy.

Conclusion

NFPA 660 provides a comprehensive framework to help safeguard your employees, facility and community from one of the most dangerous industrial hazards—combustible dust. Aligning with this standard meets insurance and regulatory requirements and ensures you’re implementing leading-edge safety practices. The most important step is to start now: educate your team, assess dust hazards and systematically apply the standard’s requirements.

Compliance isn’t a one-time effort. NFPA 660 is on a three-year revision cycle, with updates anticipated in 2027. Building a strong program today will make it easier to adapt to future changes and maintain compliance with minimal disruption.

Tackling combustible dust safety may feel overwhelming, but you don’t have to do it alone. Camfil APC’s experts are here to help you interpret and implement NFPA 660 effectively. We stay up to date with all NFPA standards and offer a full range of dust collection systems, installation services and compliance support to make your facility safer.

Be proactive. Don’t wait for an incident or inspection to uncover gaps in your safety program. If you have questions about NFPA 660 or need help with compliance, contact Camfil APC for a consultation. Together, we can create a customized strategy to eliminate dust hazards and ensure your operation meets the latest standards.

[1] https://www.osha.com/blog/general-duty-clause

[2] https://www.osha.gov/enforcement/directives/cpl-03-00-008

[3] https://codes.iccsafe.org/content/IFC2024P1

[4] https://codes.iccsafe.org/content/IBC2024P1

[5] https://www.nfpa.org/codes-and-standards/nfpa-660-standard-development/660

[6] https://community.nfpa.org/