Dust Collector Maintenance Solutions

Ensure long-term performance and reliability with Camfil APC’s Preventative Maintenance Program.

Confidence Backed by Camfil for All Dust Collector Brands

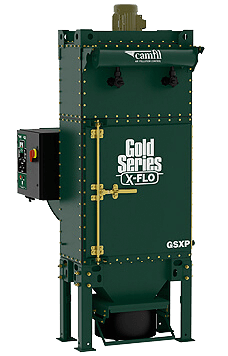

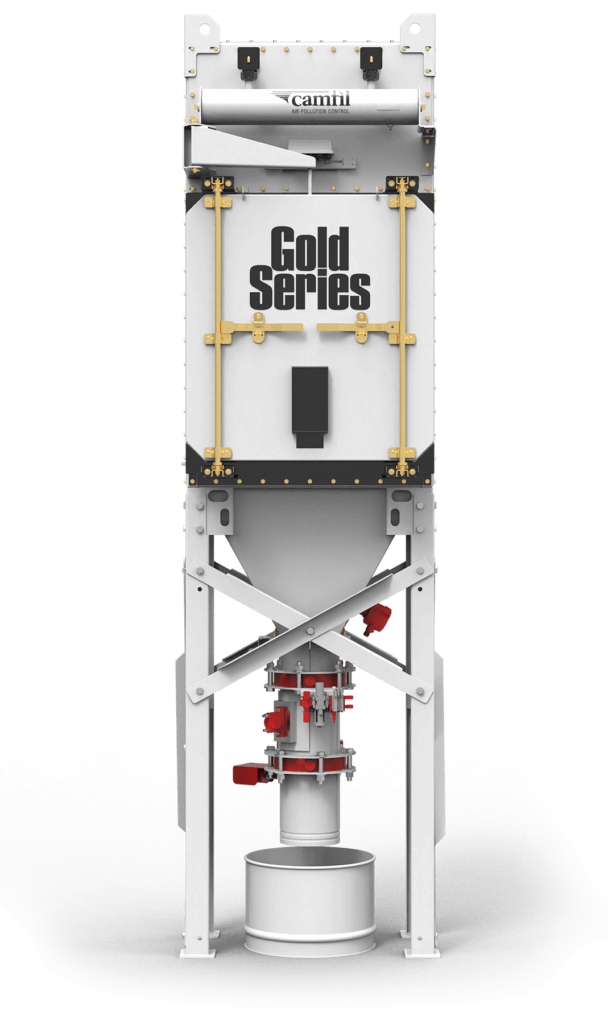

Our service offers the confidence that comes with owning and operating a Camfil APC dust collector—and we proudly extend this support to non-Camfil systems as well. Camfil provides customizable service plans tailored to meet your specific application needs.

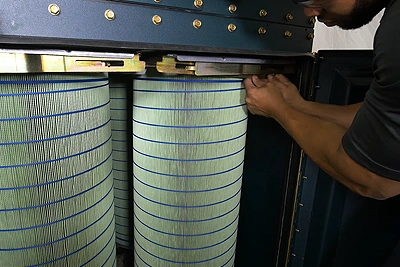

Plans can include filter changes, replacements and proper disposal, minimizing downtime and keeping your system running efficiently.

As part of our service, a qualified service specialist will inspect your system for signs of moisture, contamination and wear. When needed, our specialists will also conduct system balancing, airflow measurements and leak detection tests to maintain optimal performance.

Whether your equipment is from Camfil or another manufacturer, we have service contracts to suit your needs.

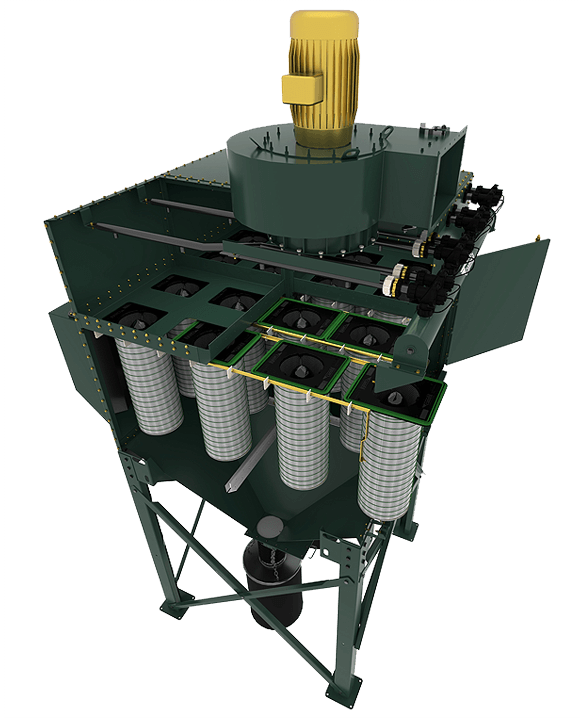

System and Performance Checks

Provided During Each Visit

System and Performance Checks Provided During Each Visit

- Solenoids

- Diaphragm Valves

- Controller Operation

- Air Pressure Settings

- Filter Regulator Clean-out

- Airline Leakage

- Moisture Check

- Abrasion Issues

- Door Gaskets

- Clean Air Plenum for Dust

- Cam Bar Operation

- View Filters for Abrasion

- Clean Spark Baffles/Inlet Baffles

- X-Vent Seal and Perforations

- Check Inlet for Cleanliness

- Dust Accumulation

- Leakage

- Cleaning

- Factory Certified to Service

- Explosion Vents

- Isolation Dampers

- Spark Detection Systems

- Fire Suppression Systems

- Explosion Isolation Systems

- Hopper to Filter Connection

- Hopper Cleaning

- Airlock Service

- Check Slide Gates

- Check Drum Cover Kit

- Check All Supporting Hardware

- Blower Amperage Draw

- Belt Replacement and Tension Checks

- Grease Bearings

- Damper Settings

- Investigate Design Airflow vs. Performance

Americas

Americas