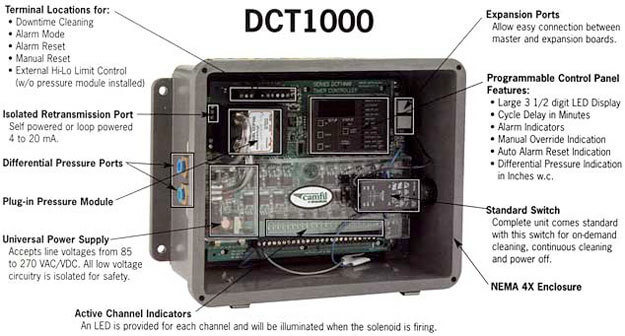

DCT1000 Dust Collector Controller

Built for:Dust & Fume

Key Features:

- NEMA 4X enclosure with on-demand continuous cleaning and power off.

- Universal power supply accepts 85-270 VAC/VDC at either 50 to 60 Hz.

- Modular design allows for use as a continuous or on-demand cleaning control

- Retrofit-compatible with other industrial dust collectors.

- Same size for 6, 20 and 22 channels. One board size means you standardize on one enclosure.

- Alarm relays integral to the optional plug-in pressure module eliminate the additional cost for a pressure switch.

- 4-20 ma process output integral to the plug-in pressure module. No need to purchase an expensive process transmitter.

- Latching relays and jumper wires are eliminated for large installations requiring channel expanders. Each channel expander connected is automatically detected by the DCT 1000.

The DCT1000 Dust Collector Controller was designed to be used with pulse-jet type industrial dust collectors for on-demand or continuous cleaning applications.

Continuous cleaning applications do not require external inputs and can be used for time based "on-demand" cleaning through use of the cycle delay feature.

For on-demand applications, the plug-in pressure modules can be used to take full advantage of all the features the DCT1000 offers, or an external pressure switch (such as the Dwyer Photohelic®) can be used for High/Low limit control.

The DCT1000 was designed so that it is easy to use, thus allowing for a quick and easy start up for your dust control applications.

Americas

Americas