Sink Manufacturer's Dust Problems Down the Drain - Sink Factory, Inc.

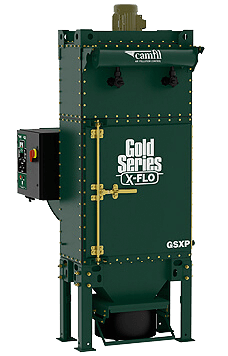

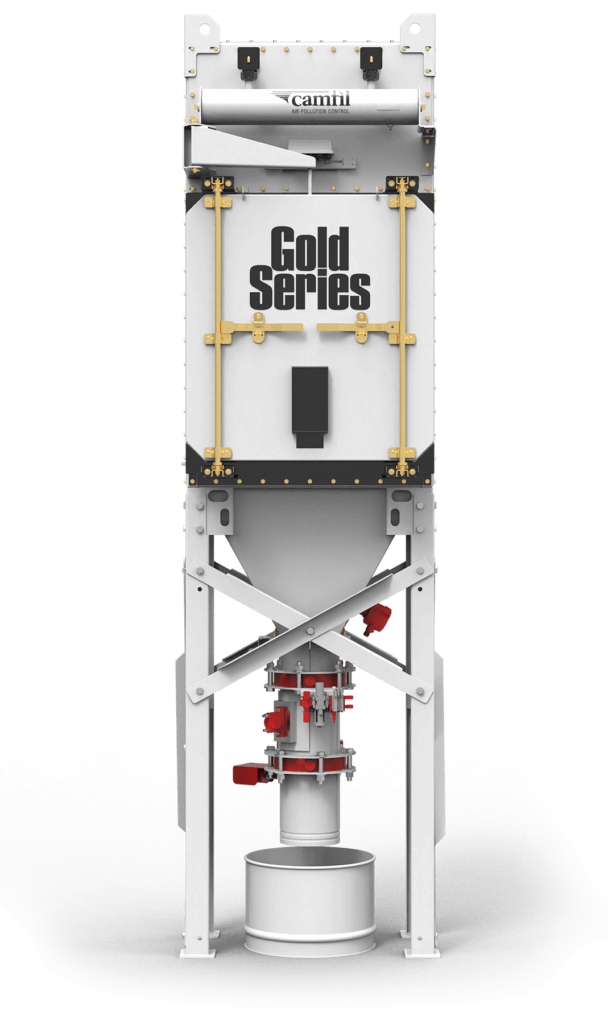

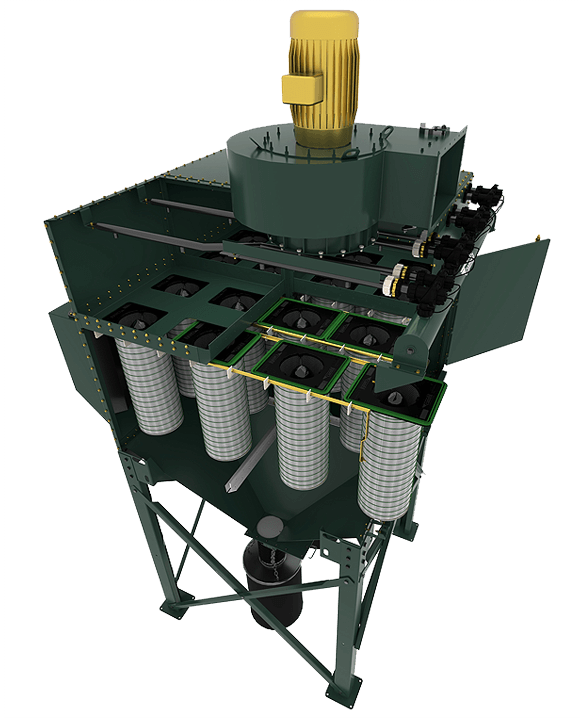

Challenge Sink Factory, Inc. (SFI) is a manufacturer of cast polymer products. In 2004, they started their business in a facility that already had a baghouse dust collector in place. However, the volume of dust generated by the grinding and sanding of the cast sinks proved to be too great a challenge for the undersized collection system. Employees with protective...

Americas

Americas