World Leader in Agriculture Spraying Technology Grows with Gold Series®

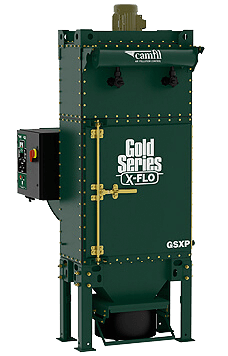

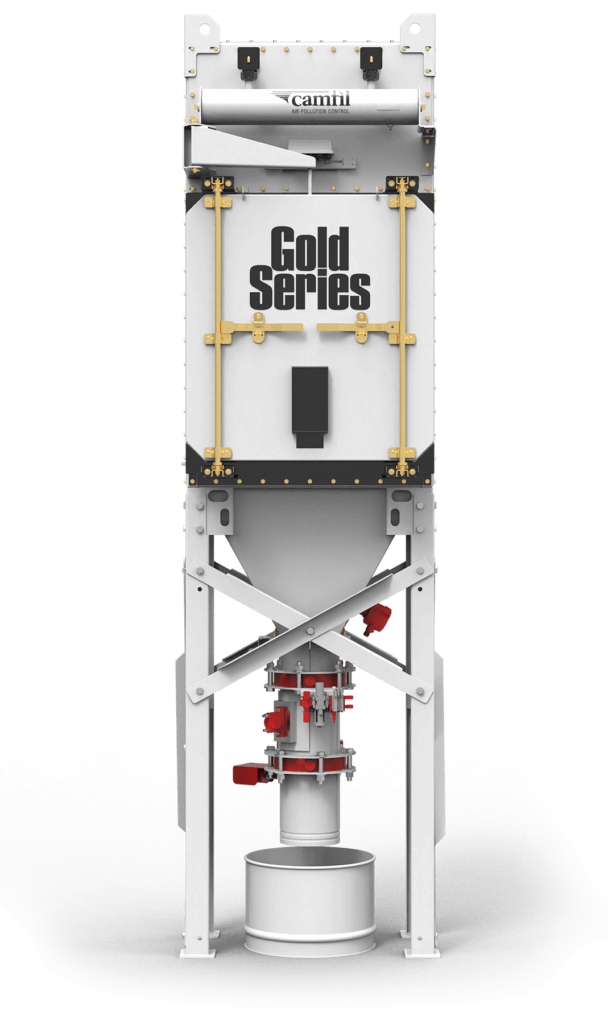

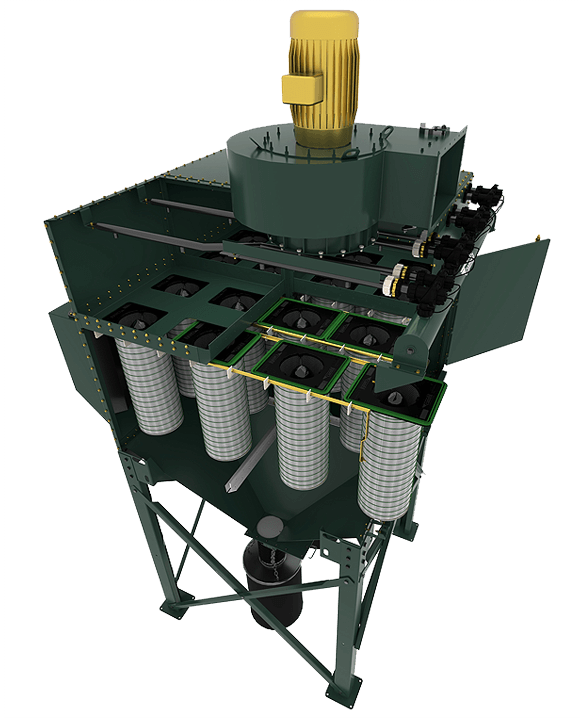

Challenge Established by gardener Hartvig Jensen in 1957, Hardi is a world leader in industry, consumer, and agriculture spraying technology. Hardi sells to more than 120 different countries and has a worldwide staff of approximately 1,050 people. With 15,000 square meters of modern development, manufacturing and distribution facilities, Hardi’s South Australian Facility needed a renovation that included a new Abrasive...

Americas

Americas