Recently, Camfil APC’s Brian Richardson worked with a woodworking company facing a challenge: proving National Fire Protection Association (NFPA) compliance to its landlord’s insurance provider. With 45 years in the business, the company made numerous modifications to its dust collection system over time with various add-ons. Needless to say, the system wasn’t in NFPA compliance.

Seeking a compliant solution, the business owner encountered frustration as multiple vendors proposed solutions that failed to achieve NFPA compliance. Adding to the challenge, one vendor misinterpreted NFPA regulations and even suggested an underhanded strategy to bypass the insurance auditors without achieving full compliance by purchasing a partial system and adding on to it later.

NPFA Experts

The business owner contacted Richardson, who outlined the essential NFPA rules from standard 664 for woodworking facilities and charted a course for achieving compliance. Camfil APC was able to prevent a temporary shutdown of the business by providing the insurance provider with a timeline for completing the compliant system.

Watch the Full Switching Story

To get the full story, watch Brian in this Facing NFPA Guidelines video.

Why NPFA Compliance Matters

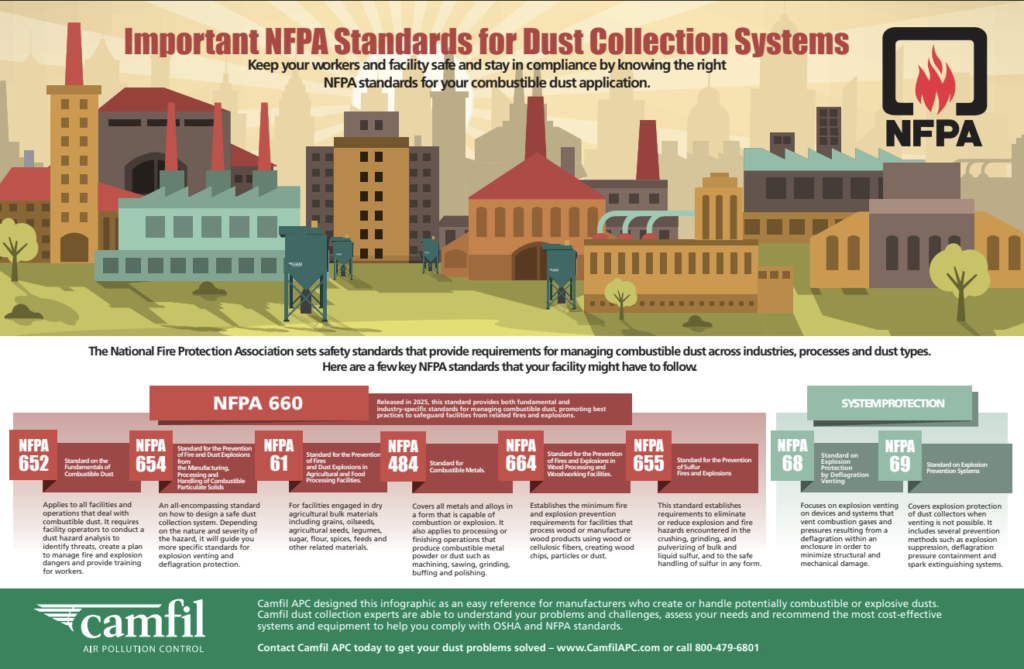

When facilities use processes generating dust, they must be prepared for potential combustible dust explosions. The NFPA provides guidelines for the safe handling of combustible dust. Insurance providers and local fire ordinances often require facilities adhere to NFPA standards.

In addition, the Occupational Safety and Health Administration (OSHA) references these standards when assessing hazards and identifying safety infractions. Failure to comply could lead to OSHA fines and penalties. Most importantly, NFPA compliance is crucial for protecting both your employees and property from potentially devastating combustible dust incidents.

The Crucial Role of Properly Designed Dust Collection Systems

Keeping your facility clean is vital for eliminating dust from the air and surfaces where it builds up over time. This not only lowers the risk of explosions but also improves indoor air quality. To further reduce the presence of combustible dust, it's crucial to have a properly designed dust collection system customized for your specific processes.

However, it’s important to note that even the dust collector itself can pose a risk. That's why having a properly designed system, including explosion protection equipment, is crucial to prevent dust collectors from becoming sources of combustible dust explosions.

Dust Dangers in the Woodworking Industry

Facilities who manufacture wood products like furniture often overlook the danger of wood dust. These tiny particles of wood fiber present two major threats if left unchecked in the woodworking environment. They can infiltrate workers' respiratory systems, causing a range of health problems. They can also contribute to environmental pollution, worsening respiratory conditions within the wider community.

Click here to learn more solutions to mitigate woodworking dust or email .

Americas

Americas