Process manufacturing often generates fine dust particles as a byproduct of normal operations. These particles, once they become airborne, often take time to settle out of the airstream and may pose issues with product quality control, require additional housekeeping, or even present serious health and safety issues if left unaddressed.

As highlighted in the recent article in Industrial Safety & Hygiene News, “Breathe Easy: Understand the Role Dust Collectors Play in Maintaining Safe Industrial Facilities,” by Tony Galvin, pharmaceutical segment manager for Camfil Air Pollution Control (APC), dust collectors are heroes of industrial safety. Galvin underscores how properly designed dust collection systems can mitigate the risks of combustible dust incidents, improve indoor air quality and ensure regulatory compliance to ultimately protect workers’ health and keep facilities running safely and efficiently.

Read further for insights to help safety managers, engineers and facility operators prioritize dust collection as a foundational element of an industrial safety strategy.

Understanding Industrial Dust Hazards in Manufacturing Facilities

Industrial processes such as mixing, grinding, cutting and conveying generate dust particulates that can range from fine powders to larger, heavier fragments, depending on the material and the application. Effectively managing these processes requires understanding both their physical properties and their safety implications. Process dust byproduct may result in:

- Nuisance dust: Nontoxic, noncombustible particles that can still create housekeeping challenges and obstruct visibility.

- Toxic dust: Dusts containing hazardous compounds, such as heavy metals or chemical residues, which require specialized containment and filtration.

- Combustible dust: Fine particulates that can ignite when dispersed in air and exposed to an ignition source.

Each type demands specific engineering controls to protect workers and comply with regulations.

Combustible Dust Risks and Explosion Prevention

Combustible dust is among the most critical safety concerns in industrial processing and manufacturing. When dust accumulates in hidden areas or becomes suspended in the air, it can create an explosive atmosphere. Even a small spark or static discharge can ignite these clouds, leading to devastating fires and explosions.

To mitigate these risks:

- Implement a properly designed dust collection system with explosion protection features (such as vents and isolation valves).

- Regularly clean surfaces to prevent accumulation.

- Conduct hazard assessments and follow NFPA (National Fire Protection Association) standards.

“Given the complexity of explosion protection, partnering with an experienced vendor is critical. Your equipment provider should help you navigate NFPA standards, local codes and requirements from your authority having jurisdiction (AHJ), ensuring a complete and compliant solution,” Galvin advises in the ISHN article.

Respiratory Hazards and Occupational Health

Beyond explosion hazards, airborne dust can create significant respiratory health issues. Prolonged exposure to fine particles may lead to chronic conditions, including occupational asthma and lung disease. In the ISHN article, Galvin says, “Preventing employee exposure to hazardous dust during equipment maintenance is critical, and in most scenarios a combination of physical containment and operational isolation is necessary to safeguard personnel and maintain process integrity.”

Cross-Contamination Risks in Multi-Process Facilities

In facilities handling multiple products or processes, airborne dust can migrate between production lines, leading to cross-contamination. This is especially problematic in industries like food processing, pharmaceuticals and chemicals, where strict purity standards apply. Well-engineered dust collection systems prevent this migration by capturing particulates at their source and filtering them effectively.

Economic Impact of Dust-Related Incidents

Dust hazards also carry substantial economic consequences. Fires and explosions can lead to costly shutdowns, regulatory fines, equipment damage and loss of business continuity. Investing in reliable dust collection and control not only improves safety but also protects profitability by preventing unplanned downtime and reducing liability.

Regulatory Framework for Industrial Dust Collection Systems

Effective dust collection systems are not just recommended, they are required by numerous regulatory agencies to protect workers, facilities and the environment. Understanding these regulations is critical for any organization committed to safe and compliant operations.

OSHA Requirements for Dust Control and Worker Protection

OSHA enforces standards that limit workers’ exposure to hazardous dust. Under OSHA’s General Duty Clause and standards such as 29 CFR 1910 Subpart Z (Toxic and Hazardous Substances), employers must implement controls to maintain airborne contaminants below established permissible exposure limits (PELs).

Engineered dust collection systems are often the most effective way to achieve compliance, as they capture dust at its source before it disperses into occupied areas. In addition to PEL requirements, OSHA also mandates training, hazard communication and recordkeeping to protect employees from exposure.

NFPA Standard for Combustible Dust Management

NFPA Standard 660 on Combustible Dusts and Particulate Solids comprehensively addresses the risks associated with combustible dust. By combining several earlier NFPA dust-related standards into a single unified resource, NFPA 660 streamlines compliance efforts and offers a more consistent framework for controlling combustible dust hazards across diverse industries.

In addition to standard 660, NFPA also provides the following related standards:

- NFPA 68: Standard on Explosion Protection by Deflagration Venting

- NFPA 69: Standard on Explosion Prevention Systems

- NFPA 499: Recommended Practice for the Classification of Combustible Dusts and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas

EPA Regulations on Air Quality and Emissions Control

If a facility is exhausting filtered air from an industrial dust collector to the outdoors, it is subject to the EPA National Emission Standard for Hazardous Air Pollutants (NESHAP) Rule 6x. Facility operators also must perform an EPA Method 22 Fugitive Emission test per NESHAP Rule 6x. The test is conducted using a visual determination of fugitive emissions from exhaust sources and is performed by a trained observer.

Industry-Specific Safety Standards

Many industries have additional standards that supplement OSHA, NFPA and EPA regulations. For example:

- Pharmaceutical manufacturers must comply with FDA cGMP guidelines requiring containment and control of dust to prevent cross-contamination.

- Food processing facilities follow stringent hygiene requirements to avoid contamination and allergen risks.

- Metalworking operations handling aluminum, magnesium or titanium dust must address unique combustibility and health hazards.

Connecting Compliance to Effective Dust Collection

In the ISHN article, Galvin explains that by integrating high-efficiency filtration, containment and explosion protection in a single engineered dust collection solution, manufacturers can achieve safer working environments while meeting all applicable codes and standards. This proactive approach reduces liability and inspection risk, protects employees and supports long-term operational performance. He also notes the importance of partnering with an experienced provider of dust control solutions that can help you meet the unique demands of your facility, city and state.

Real-World Examples of Safety Improvements

Manufacturing plants around the world have achieved substantial improvements in both safety and operational performance by upgrading to Camfil’s dust collection systems. For example:

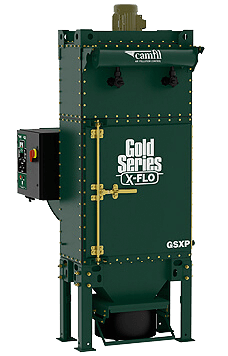

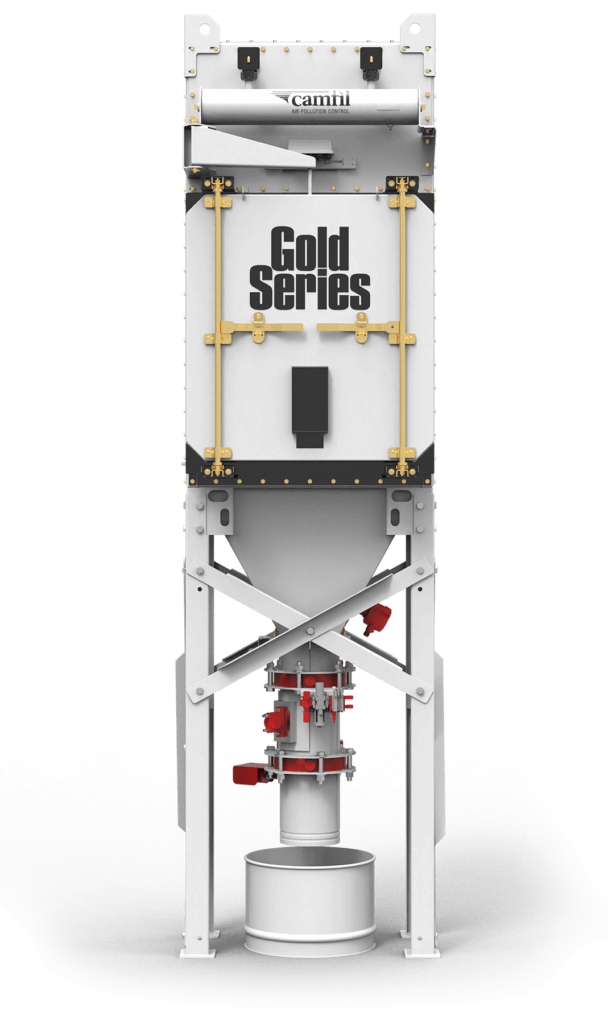

- Precision Press, Inc., a printing, labeling and packaging company in North Mankato, Minnesota, faced persistent dust management problems. Paper and plastic scrap, along with fine dust, were processed through a cyclone baghouse dust collection system that required frequent maintenance. To resolve these issues, Camfil APC strategically installed GS24 and GS16L Gold Series® industrial dust collectors. These systems included variable speed drive blowers and advanced controls to lower energy consumption. The clean air returned into the facility created a cleaner, warmer environment while reducing energy costs.[1]

- Nestlé USA relied on Camfil APC to design a system to capture food dust at the source using stainless steel pickup hoods at each mixing station. These hoods pulled the airborne particulates away from the employees into ducting that leads to the Gold Series industrial dust collectors located at the rear of each room. The design featured larger dust collectors with explosion protection to address the combustible dust.[2]

- Ogihara America Corporation, a manufacturer of automotive body parts, reached out to Camfil APC to control dust from sanding and grinding operations. Camfil recommended the specialized installation of multiple Gold Series industrial dust collectors with HemiPleat® filters. The Gold Series booths enclose and isolate each of the ten workstations and occupy a minimum of valuable floor space.[3]

These examples underscore that investing in effective dust collection is a proactive strategy that pays dividends in safety, compliance and productivity.

Camfil APC Industrial Dust Collection Solutions for Enhanced Safety

Camfil APC offers a comprehensive range of dust collection solutions to improve safety and compliance in industrial facilities. Their systems are engineered to address the most demanding requirements for protecting workers, equipment and operations from the hazards associated with airborne contaminants and combustible dust.

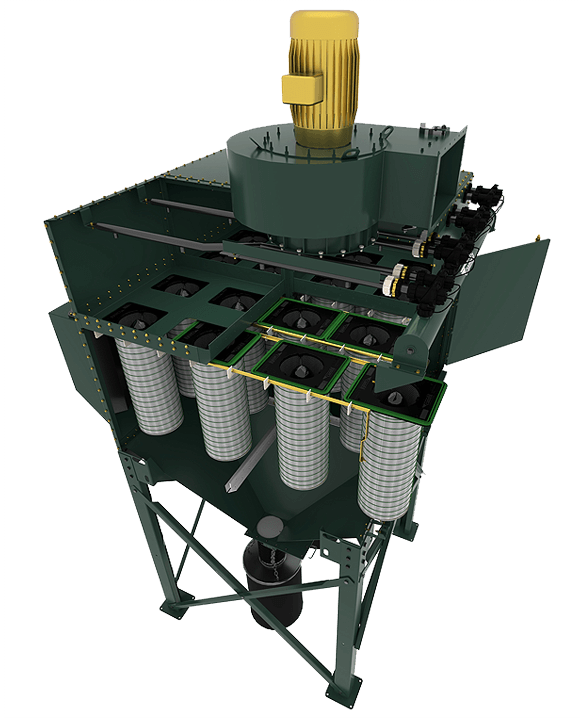

Comprehensive Safety-Focused Dust Collection Portfolio

Camfil APC’s product lineup includes the Gold Series dust collectors, renowned for their modular design, high filtration efficiency and adaptability to a wide range of industries from metalworking and pharmaceutical production to chemical and food processing. They handle all kinds of toxic and combustible dust, smoke and fumes, including fine, fibrous and heavy dust loads. These collectors are designed to meet or exceed OSHA and NFPA standards while providing dependable performance even in challenging environments.

Advanced Filtration Technologies for Industrial Safety

Camfil APC’s collectors leverage proprietary Gold Cone™ filter cartridges and HemiPleat filter technology, which uses open-pleat spacing and uniform pleat height to maximize surface area and extend filter life. The result is cleaner air, improved protection for workers and lower operational costs thanks to longer filter service intervals.

Dust Collector Explosion Mitigation

Although it isn’t always possible to prevent explosions in dust collectors, you can incorporate protective measures to minimize their impact. Critical explosion protection strategies play an essential role in reducing the risk of harm and mitigating potential incidents.

- Explosion vents allow the pressure and flame front to exit from the dust collector in a safe direction.

- Explosion isolation valves prevent flames and pressure from traveling through the inlet ducting into the process area.

- Integrated safety monitoring filters isolate downstream equipment from the progression of a flame front during an explosion.

Maintenance and Service Programs for Ongoing Compliance

Staying proactive about maintenance is one of the most effective ways to keep your dust collection system performing at its best. That’s where Camfil APC’s Preventative Maintenance Solutions make the difference. Whether you rely on a Camfil APC dust collector or use equipment from another manufacturer, Camfil delivers customized service plans to help your operation stay clean, efficient and compliant.

With preventative maintenance support from Camfil APC, you benefit from more than routine inspections. Comprehensive support includes:

- Filter changes and disposal

- System inspections

- System balance evaluations

- Airflow measurements

- Leak trace testing

These services go well beyond surface-level checks, giving you peace of mind that the dust collection system is maintained to the highest standards.

Dust Collection System Selection

As Gavin notes in the ISHN article, “There is no one-size-fits-all in dust collection, and effective systems are sized according to specific process requirements including: the type of dust generated, proposed location of the dust collector, airflow and static pressure requirements, and industry-specific safety requirements.”

Common dust collection systems used in industrial environments include:

- Cartridge dust collectors

- Baghouses

- Wet scrubbers

- Portable dust collectors

Recognizing how each type of collector aligns with the unique demands of your operation is critical to selecting the right system for your needs.

Conclusion

Effective dust collection is more than a regulatory requirement; it is a cornerstone of industrial safety. The ISHN article by Tony Galvin underscores this point clearly: investing in advanced dust collection systems creates safer workplaces and more resilient operations.

With decades of experience and a comprehensive portfolio of dust collection technologies, Camfil APC is uniquely positioned to support facilities in assessing hazards, designing effective systems and maintaining compliance over the long term.

For additional expert insights, be sure to read the full article from Industrial Safety & Hygiene News:

Breathe Easy: Understand the Role Dust Collectors Play in Maintaining Safe Industrial Facilities – ISHN.

[1] https://camfilapc.com/case-studies/farr-gold-series-exceeds-sustainability-challenge/

[2] https://camfilapc.com/case-studies/food-industry-leader-takes-bite-tradition/

[3] https://camfilapc.com/case-studies/body-parts-processed-clear-lungs-farr-booths/

Americas

Americas