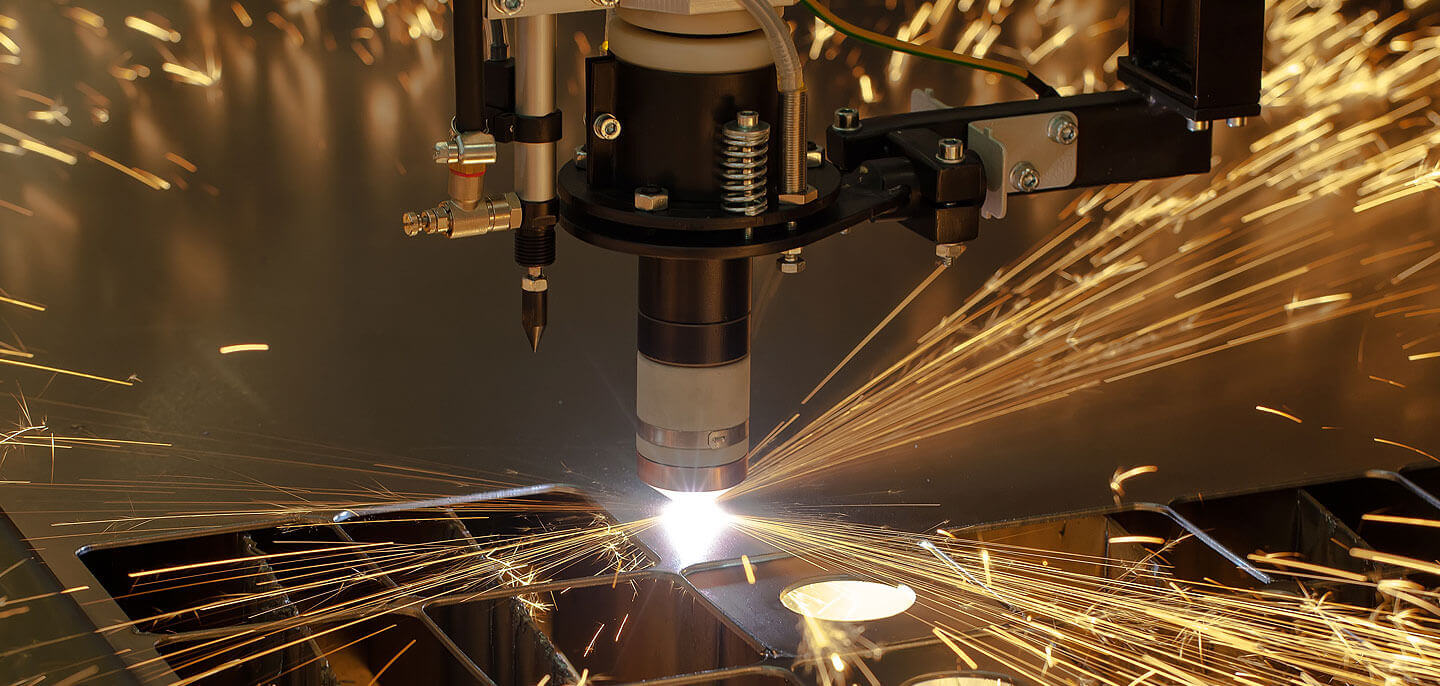

This Laser Cutter Fume Extractor Safely Captures Dangerous Airborne Particles

There have been many changes in laser cutting technology, including new metal thicknesses and more varieties of metal including mild steel, stainless steel, copper and brass. Today's fiber laser tables generate molten metal, smoke, and gases, which can be breathing hazards for machine operators. Good ventilation is required to prevent inhalation of toxic airborne particles, particularly the tiniest particles that can settle deep into lung tissues.

Dust collectors are most commonly used to capture particles at the source. Dust, fumes and smoke are pulled down through the table and removed through the duct-work where they are filtered through the dust collector. The dust collector’s filter cartridges capture all particles until they can be safely removed.

Laser wattage, type of beam, material being cut, type of assist gas, automated material handling system and table size all play a role in determining collector size and airflow. So be sure to consult a Camfil APC expert to size the correct laser cutter fume extractor to solve your laser dust/fume/smoke problems.

Download the white paper today

This white paper examines health risks, fire and explosion hazards, equipment design considerations, maintenance and operational factors, and the benefits of air recirculation downstream of the fume extractor.

Learn this and more in the FREE White Paper

GOLD SERIES® X-FLO PACKAGED (GSXP) SYSTEMS FOR LASER CUTTING OPERATIONS

The Gold Series X-Flo Package is a plug and play dust and fume collection system that is ideal for laser cutting applications where floor space is at a premium. The units are available in three sizes (2, 4 or 6 filter cartridges) and ship completely assembled and ready to plug in. All internal electrical connections, dust collector timer controls and fan controls are included, and accessories such as smoke detectors are factory-wired. Includes features like cam-lift dust drawers and a built-in air damper.

- Available in three sizes (2, 4 or 6 cartridges). All access to components (including controller, compressed air supply, access door, discharge drawer and integrated inlet damper) is on the front side of the collector for ease of use.

- Inlet damper is integrated into the collector as a standard feature. Damper is sized for appropriate airflow for the size/model.

- Discharge system features a 20-gallon drawer with sliding casters and a cam-operated lift device.

- Compact collector footprint with top-mounted fan saves space.

- Diaphram valves are mounted low for maintenance accessibility.

- Fire sprinkler in the clean air plenum provides more effective fire suppression.

- Smoke detector sends a signal to the dust collector to shut off the fan if it detects smoke in the clean air plenum.

Americas

Americas