StingerTM Explosion Isolation Valves

Built for:Dust & Fume

Key Features:

- Third party tested to EN16447 to be NFPA 69 Compliant

- Passive flow activated design requires less maintenance

- Light weight flap reduces pressure loss and energy cost

- Welded steel explosion pressure resistant design

- Self adjusting locking mechanism

- Easy access inspection door

- Optional valve activation sensor

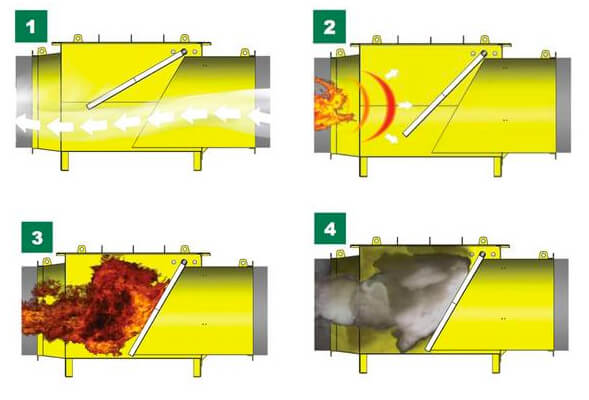

Passive Valve Operation

The Stinger explosion isolation valve prevents explosion flame and pressure from propagating through the inlet ducting and into the process area.

Flow Activated Flap Valve

Process air flow moves the flap plate to the fully open position. Explosion pressure moves the flap to the closed and locked position, isolating the explosion flame and pressure from personnel and equipment down stream of the dust collector.

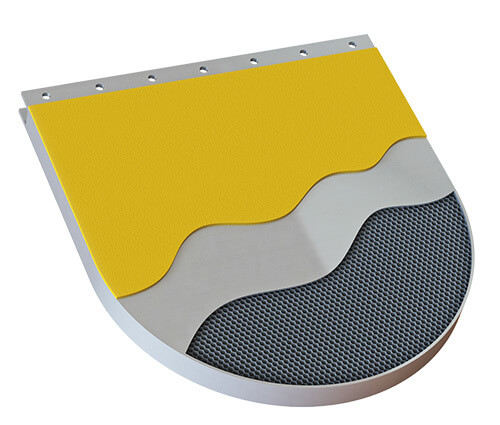

Composite Flap Advantages (Patent Pending)

- Lower flap weight

- Lower pressure drop

- 3 mm wear resistant anti-static, flame retardant liner

- High strength to weight ratio

- Smooth back surface of blade reduces dust accumulation

- Easily replaceable

- Absorbs explosion impact forces