Controlling Mining Dusts

It's very challenging to control dust from mining processing equipment, such as crushing, screen, and conveyor transfer points. Both the Mine Safety and Health Administration (MSHA) and the Environmental Protection Agency (EPA) are working with mining companies to reduce dust emissions around mine sites to protect people and the environment. Both agencies have strict limits on dust emissions. If emissions are too high, production schedules may be curtailed and fines can be imposed. This is why proper design and selection of dust control equipment is an important concern.

In addition to meeting regulatory requirements, reducing emissions protects personnel, improves the air quality of surrounding areas, and reduces wear and tear on production equipment. A proper dust collection system offers reliable operations and ease of maintenance.

The Farr Gold Series industrial dust collector is uniquely suited to meet the requirements of the mining industry in the 2.5 micron and 10 micron size Particulate Matter (PM) ranges. It is extremely rugged with a heavy-gauge construction and a modular design that optimizes field flexibility in harsh mining environments.

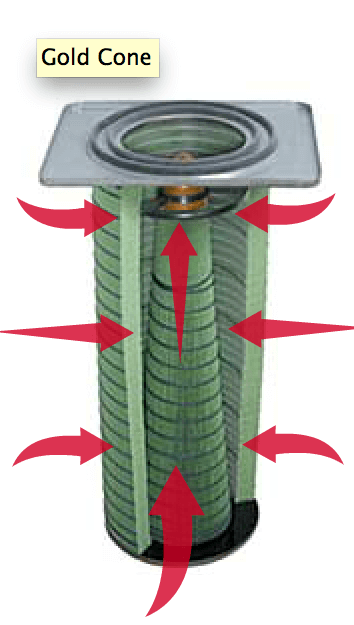

What sets Camfil APC apart as the leader in high-efficiency filtration design is the Gold Cone cartridge filter. This filter combined with our unique collector design results in a solution that works well in a harsh mining environment.

Farr Gold Series Dust Collector Operating at a Conveyor to Conveyor Transfer Station

Excavation Sites

• Large open-pit mines

• Quarries

• Underground operations

Coarse and Fine Ore Processing Plants

• Primary crushing and overland conveying

• Secondary and tertiary fine ore crushing, screening and conveying

• High pressure grinding (HPGR), high pressure roll crushing (HRC) and conveying

• Crushed ore storage bins

• Lime storage silos

• Assay labs for processing core samples

• Pressuring electrical control rooms

Video: Expert Discusses Dust Collection for Mining

- Abrasion-resistant inlet with slanted baffle

- UHMW inlet wear liner

- Outlet stack extension with test port

- Stainless steel tubing between solenoid and diaphragm valves

- Quick closing valve for diaphragm valve

- Heavy-duty rotary airlock with chrome lining

The items below display the elements and functionality of mining dust collectors.

A. Gold Cone®HemiPleat® Filter Cartridge

B. Inlet Baffle Wear Design

C. UHMW Wear Compound

D. Rotary Airlock with Chrome Lining, Tenv Mill/Chem w/ Zero Speed Switch

One of the main concerns with cartridge dust collectors is how well the pleated cartridge design will hold up against moisture. Will the moisture in the ore present plugging problems?

Not with the HemiPleat®. Take a look at the standard "dimple-pleat" separation method versus the Gold Cone® filter with HemiPleat pleating technology:

Standard Dimple-pleat Separation Method

Camfil APC's Exclusive HemiPleat Design

Video: HemiPleat Pulse Cleaning

The key to the HemiPleat's superior performance is Camfil APC's exclusive, state-of-the-art pleating technology. Synthetic beads hold the pleats of the cartridge open with wide pleat spacing. In comparison, the pleats in competitive cartridges are packed too tightly to maximize media use, especially in mining applications. The wider spacing of the HemiPleat design improves cartridge release characteristics during pulse cleaning, greatly reducing the potential for plugging. For high moisture applications, we have our Dura-Pleat filter. This filter shares a design with the HemiPleat but uses a spun-bond polyester material to ensure moisture will not degrade filter life.

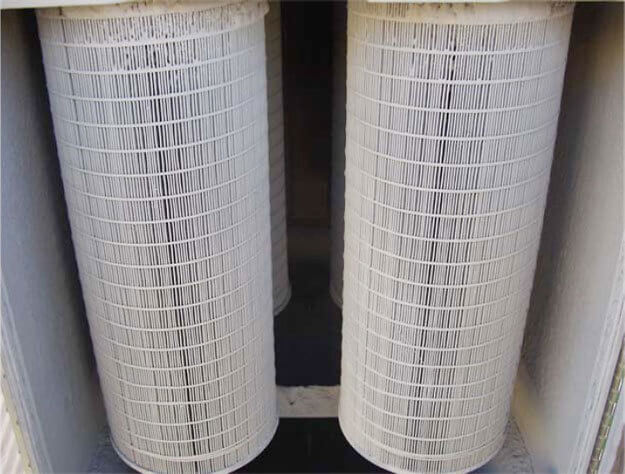

Gold Cone cartridge filters near the 2-year mark in operation on a mining application.

- Unimin Corporation

- Freeport-McMoRan Copper and Gold

- Grupo Mexico

- Southern Peru Copper

- ASARCO

- CODELCO

- Ravensthorpe Nickel

- Barrick Gold

- Carlota Copper

- Goldcorp

- SIMCALA

- Oglebay Norton Specialty Minerals

- KGHM

- Lake Shore Gold

- Hudbay Minerals

- Yamana Gold

- Centerra Gold

- Teck

- Antamina

- Minera Suyamarca

- Compañía Minera Alpamarca SAC

- Mesabi Nugget

- Frontera Copper

- United Taconite

The Éléonore Project- Building a World Class Mine

Watch Video

Which type of dust collection system will save money over time, a traditional baghouse or cartridge-style collector?

Resources and Literature:

GOLD SERIES INDUSTRIAL DUST COLLECTOR

Gold Series dust collectors perform well in applications where dry materials are batch mixed, conveyed and processes. It offers high performance, a modular design, ease of service, and an optional bag-in, bag-out filter change out. Constructed from heavy-duty carbon steel to meet the demands of your application, the Gold Series has unparalleled strength and life compared to the competition. Coupled with Gold Cone™ vertical cartridge technology, the Gold Series offers superior pulsing of high-loading dust while simultaneously utilizing the smallest floor space of any dust collector available today.

- High-efficiency filters stop 99.99% at 0.5µ of the dust.

- Unique high-entry inlet design allows large particles to drop out, eliminating can velocity and giving longer filter life.

- Specially treated filter media repels the fine particle for lower pressure drop and long filter life.

- Exceeds the lowest emissions requirements for compliance stack testing with results of less than 0.001 gr/dscf on hard rock crushing screening and conveying operations.

Two Farr Gold Series FGS96 Units at a Nickel Mine

When sizing up the dust collector system for the intended operation, mining applications require a specific, maximum air-to-cloth ratio. Camfil APC has professional personnel with many years of experience in the mining industry. They can review your project and propose a customized Farr Gold Series system.

Farr Gold Series capturing fugitive dust over a conveyor.

Contact us here at Camfil APC, and we will put you in touch with one of our Farr Gold Series experts for mining applications. They will work with you to size up the right system, looking at all items that could be a concern: process temperature, ambient air temperatures, condensation, wear issues, and meeting low emissions limits. You'll also learn about the necessary features and options that can solve your dust problems.

Farr Gold Series capturing fugitive dust over a conveyor.