When we discuss vertical cartridge dust collectors, we are talking about dust collectors that use filter cartridges installed vertically, versus horizontally. This blog explores why that matters.

Choosing the right industrial dust collector is crucial for optimal performance. Filters, which are the heart of dust collectors, play a key role by capturing dust, fumes and other pollutants from the air. Although cartridge-style filters are the most widely used, they come in a variety of efficiency ratings, filter media and installation orientations. One important design decision is whether the collector uses filter cartridges installed a horizontally or vertically.

You might think the orientation of the filters isn't significant, but it actually has a substantial impact. Opting for a system that has cartridges installed vertically versus horizontally can greatly influence the system's efficiency, safety and overall cost. Here’s why.

Traditional horizontal designs

In the early designs of the industry's baghouse and cartridge dust collectors, filters were installed horizontally. This setup aimed to counteract the effects of "interstitial velocity"—the speed of the airstream moving vertically between filters in the collector. Air would enter the hopper at the base of the unit and travel up into the filter housing.

For maintenance and cleaning, airflow through the filters had to be moderated so that the dislodged dust particles could fall back down through the airflow. This approach was effective for removing heavy dust, but not for lighter particles like welding smoke or fumed silica.

The design logic was that horizontal filters would shift the clean air plenum to the collector's side, leaving the dirty air plenum on top. This rearrangement would drive air to the top of the dust collector, creating a downflow effect that would counteract the interstitial velocity.

However, laying a filter on its side presents many drawbacks. A major problem is the inability to clean the dust off the filters thoroughly. Dust tends to accumulate on the top of the filters and is not entirely removed by the pulse cleaning process, leading to a blockage of at least a third of the filter surface. Consequently, this increases the air-to-media ratio and can lead to early system failure due to the excessive burden on the filters.

Another major issue with horizontal cartridge dust collectors is the direct deposition of dust. Every particle entering the system settles onto the filter cartridges without any prior separation, a particular problem with heavier and more abrasive particles. This not only hampers filter efficiency but also poses a safety hazard. If a spark were to enter the collector, it would land directly on a filter, creating the potential for a dust explosion or fire.

Moreover, during the pulse cleaning process, most of the dust dislodged from the top filters falls onto the ones below. In fact, horizontal filters may experience up to a 20 percent reduction in airflow due to the dust accumulation. This leads to a cycle of recontamination, reducing the effectiveness of the cleaning process and potentially causing uneven wear or damage to the filters.

A better solution...vertically oriented filter cartridges

Vertical cartridge dust collectors resolve problems associated with horizontal cartridges...dust piling on the top and falling onto the filters below on the way to the hopper.

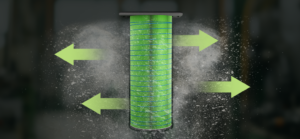

The vertical arrangement allows gravity to aid the pulse cleaning process. Dust and debris are forced out of the cartridges and drop straight into the hopper, preventing the problem of contaminating the lower-lying filters.

This efficient method of dust removal prevents filters from becoming prematurely clogged. This results in less frequent filter replacement and reduced energy costs, which can significantly lower overall operational expenses. Additionally, vertical cartridges are more accessible, which cuts the time associated with maintenance for even greater cost savings.

The design of vertical cartridge dust collectors extends the lifespan of filters by preventing the issue known as interstitial velocity. In addition to its vertical orientation, a high-entry inlet is positioned so that air flows into the side of the collector, preventing upward interstitial can velocity.

Dust is drawn into the collector’s inlet at the same height as the cartridges. Then the air passes through a series of staggered channel baffles that evenly distribute it across the filter cartridges. These baffles serve a dual purpose: first, they guide the air, and second they act as a pre-filter by capturing larger particles and allowing them to fall directly into the hopper, before they reach the cartridges.

This crossflow effect eliminates upward interstitial velocity. Since the air is brought into the collector at the cartridge level, air no longer flows upward toward the filters. The system combines the advantages of a downflow-style air pattern and vertical filter placement.

Vertical Filters Paired with HemiPleat Gold Cone Technology

It is already easier to load and change filters with vertically oriented dust collectors, but installation is further simplified with the easy-grip rectangle pan on a HemiPleat Gold Cone filter.

HemiPleat filters are designed with pleats that increase the surface area exposed to the air, which helps them stay cleaner and last longer compared to traditional pleated filters. These filters can handle more dust, which gets loaded onto the vertical filter and is then efficiently removed during the pulse cleaning process

The combination of vertical filter installation, crossflow air intake, and advanced H filter technology in vertical cartridge dust collectors delivers unparalleled performance and efficiency while maintaining a low pressure drop. Filter efficiency translates to lower energy costs and longer filter life.

For more information on containing dust and fumes in your facility, contact a Camfil APC product expert.