Must Read

Combustible Dust

View all combustible dust articles

Understanding NFPA 660: The New Standard for Combustible Dust Safety

Understanding how EV lithium-ion battery production machinery operates—and the emissions it generates—is essential, particularly since much of this equipment is custom-built for the industry. By combining this knowledge with Camfil’s clean air solutions, manufacturers can evaluate compliance with health, safety and environmental standards.

Eliminating the Risk of Combustible Dust Explosions in Seed Conveying Operations

Camfil Air Pollution Control collaborated with a major auto parts manufacturer utilizing dust collectors to maintain healthy air in robotic weld cells.

Installing New vs. Retrofitting Old Dust Collectors: Avoiding Hidden Dangers and Costs

Camfil Air Pollution Control collaborated with a major auto parts manufacturer utilizing dust collectors to maintain healthy air in robotic weld cells.

Customer Service and a Customized Solution are Key Reasons Manufacturer Switched to Camfil Total Dust Collection Systems

Camfil Air Pollution Control collaborated with a major auto parts manufacturer utilizing dust collectors to maintain healthy air in robotic weld cells.

Dust Safety

View all dust safety articles

How Dust Collectors Maintain Safe Industrial Facilities-Expert Insights from Camfil APC and Industrial Safety & Hygiene News

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

Pharmaceutical Dust Collection: Strategies for Oral Solid Dose Pharmaceutical Manufacturing

Learn how dust collection systems ensure safety, air quality, and compliance in pharmaceutical manufacturing of oral solid dose drugs.

Understanding NFPA 660: The New Standard for Combustible Dust Safety

Understanding how EV lithium-ion battery production machinery operates—and the emissions it generates—is essential, particularly since much of this equipment is custom-built for the industry. By combining this knowledge with Camfil’s clean air solutions, manufacturers can evaluate compliance with health, safety and environmental standards.

The Hidden Danger Inside EV Battery Plants: How Air Contamination is Slowing Down Production and Increasing Costs

Understanding how EV lithium-ion battery production machinery operates—and the emissions it generates—is essential, particularly since much of this equipment is custom-built for the industry. By combining this knowledge with Camfil’s clean air solutions, manufacturers can evaluate compliance with health, safety and environmental standards.

Factory Air Quality

View all factory air quality articles

Three Reasons to Upgrade Your Camfil Dust Collector Filters to OptiCone™ Filters

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

The Gold Standard…Elevated: Raising the Bar in Industrial Dust Collection

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

How Dust Collectors Maintain Safe Industrial Facilities-Expert Insights from Camfil APC and Industrial Safety & Hygiene News

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

Importance of Investing in a Dust Collector Maintenance Program

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

Filter Cartridges

View all filter cartridges articles

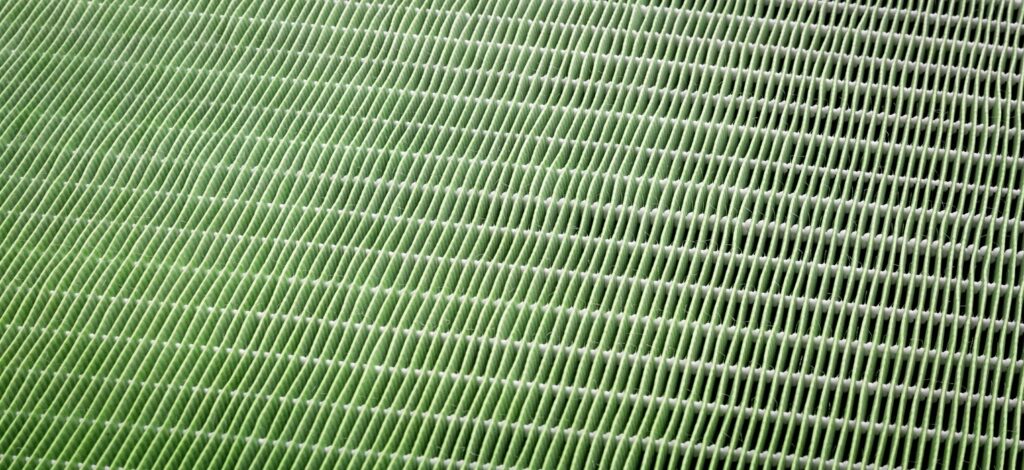

Why Filters With OmniPleat® Technology Outperform All Other Dust Collector Replacement Filters

Learn about the benefits of using OnminPleat dust collector replacement filters. Upgrading from standard filter cartridges to OmniPleat filters can boost your system performance, significantly reduce change-out, energy usage and consumable costs.

Three Reasons to Upgrade Your Camfil Dust Collector Filters to OptiCone™ Filters

Learn why a structured industrial dust collector maintenance program is far more effective than reactive repairs.

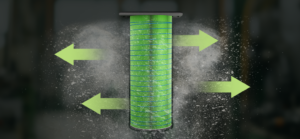

The Importance of Pulse Cleaning for Dust Collection Systems

Dust collectors typically contain multiple filters that capture the dust and other airborne particles as the airflow circulates through. Periodic pulse cleaning maintains the efficiency of the filters for the highest indoor air quality.

ASHRAE Standard 52.2 vs. ISO 16890 for Rating Dust Collector Filter Efficiency

Ensuring high indoor air quality (IAQ) in manufacturing and processing facilities is crucial for safeguarding the health and wellbeing of employees. Poor IAQ can cause symptoms such as headaches, fatigue, and eye irritation, and has also been linked to serious conditions like asthma and cancer. Research has shown that indoor air quality often falls below that of the outdoors. There...