Flour is a dust that seems innocuous on the surface. After all, could such a common household item really pose a threat to human health and safety? The answer is yes. Read on to learn about the hidden dangers of flour dust during milling and processing and how to prevent dangerous health complications and explosions at your facility.

What is Flour?

Flour is a common household food product used in baking and cooking that can be derived from grains, legumes, nuts and vegetables. This seemingly harmless powder is actually a complex mix of biologically active particles including:

- Plant material

- Bacteria

- Soil

- Insect parts

- Mold spores

- Endotoxins

How is Flour Dust Generated?

Microscopic airborne particles are released into the air during various stages of the flour milling process, particularly where raw grain enters the initial grinding area. In addition, the loading, sifting, drying and packaging areas can generate a lot of airborne dust particulates.

Commercial bakeries and other high-volume applications also can produce flour dust during activities such as:

- Loading flour and other ingredients into mixers

- Dusting flour onto baking surfaces

- Dry sweeping flour from the floor or other surfaces

- Disposing of empty flour bags

What are the Dangers of Flour Dust?

Flour dust presents two main dangers: inhalation and combustion/explosion.

Health Hazards

Breathing in grain dust can affect the health and overall comfort of workers. Most people will have some reaction to the dusty conditions present when flour dust is expelled into the air. With mild contact, a healthy person might develop a sore throat, eye irritation, cough, wheezing, chest tightness and nasal congestion. Bronchitis is also a common condition for workers who handle flour on a daily basis.

Exposure to heavy dust levels can induce symptoms that become noticeable about two to six hours after leaving work. These symptoms can include:

- Headache

- Muscle ache

- Cough

- Chest tightness

- Nausea and general ill feeling

- Fever

Very high exposure can cause medical conditions including occupational asthma, baker’s lung and organic dust toxic syndrome.

Combustion Hazards

Aside from the health hazards listed above, flour dust also poses a serious risk for combustion or explosion. Dust explosions in grain and milling industries usually start inside process equipment like mills, dryers, mixers, conveyors, storage silos and hoppers.

Flour dust explosions can cause catastrophic damage ranging from equipment damage to loss of life and injury. Grain dusts like flour are highly combustible fuel sources that can easily burn or explode upon contacting an ignition source such as:

- Overheated motors, gears and bearings

- Misaligned cover belts

- Welding, cutting or brazing

- Power surges

- Startup of production equipment after shutdown or process upset

Controlling Dangerous Flour Dust

The best way to reduce hazardous dust exposure and explosion risk is to install a dust collection system with high-efficiency primary and secondary cartridge-style filters. Primary filter media should be selected for each application based on the dust particle size, flow characteristics, quantity and distribution. If the primary filtration system does not use a HEPA filter, it is recommended that a secondary HEPA filter be used downstream to ensure hazardous dusts are not discharged into the atmosphere.

For example, the Gold Series X-Flo dust collector is ideal for agricultural and food facilities because it collects fine, fibrous and heavy dust loads at their source to prevent worker exposure to airborne contaminants and to keep dust from travelling throughout the facility. The GSX system also helps food and agricultural facilities exceed OSHA indoor air quality standards.

When equipped with a Camfil explosion vent, the GSX system offers the highest combustible dust explosion protection in accordance with NFPA standards. Other explosion protection options are available including isolation valves, integrated safety monitoring filters and fire-retardant filter cartridges.

Regulatory Standards

Occupational Safety and Health Administration (OSHA) and National Fire Protection Association (NFPA) enforce regulations and safety standards to provide a safe working environment for facilities that handle flour. These regulations include:

OSHA 1910 – general standard that covers most industries

OSHA 1928 – covers agriculture

OSHA 1910.272 – addresses grain handling facilities

NFPA 652 – general standard on the fundamentals of combustible dust

NFPA 61 – focuses on fires and dust explosions in agricultural and food processing facilities

Best Practices

Facilities that process flour or manufacture food products with flour ingredients must work to reduce the volume of dust particles in the air and minimize exposure to workers. Housekeeping tasks like vacuuming can help, but a dust collection system is the best way to reduce the threat. Cartridge-style dust collectors are today’s most cost-effective choice because they use superior filtration technology.

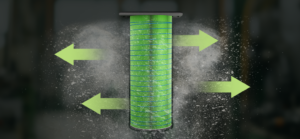

Camfil’s Gold Cone X-Flo filter cartridges (GCX) offer wide, uniform pleats that allow the collected dust to release from the filter, keeping the resistance lower through the filter for a longer time. When the pleats of the filter media are tightly packed, the reverse pulse cleaning system of the dust collector will not eject the dust that has settled in between the pleats. Tightly packed pleats increase the resistance of the air through the filters and diminish airflow.

GCX filters contain more pleated media to move more air and process more dust, so the collector creates a more uniform airflow. The filter cartridges feature specially designed inner cones with more downward-facing media than traditional filters. This extends the life of the filters and uses less compressed air. They are available with filtration efficiencies up to MERV 16 per ASHRAE 52.2:2017.

To learn more about designing a dust collection system that will keep your employees safe and your facility in compliance, contact the experts at Camfil APC.