Effective Industrial Dust Collectors for a Cleaner, Safer Workspace

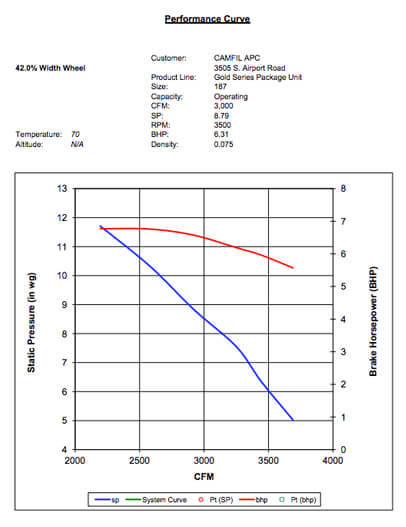

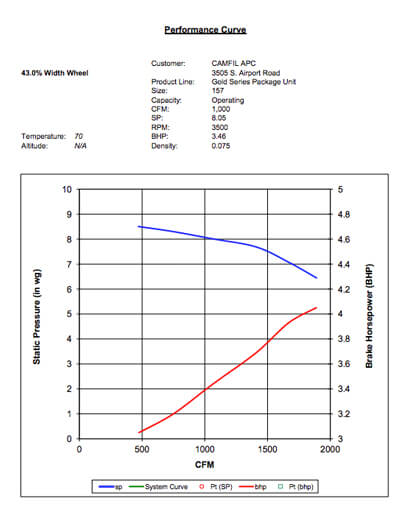

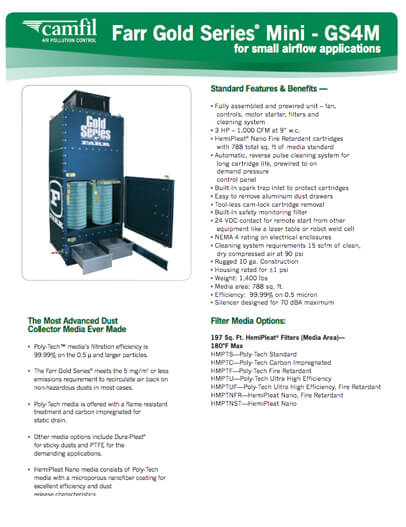

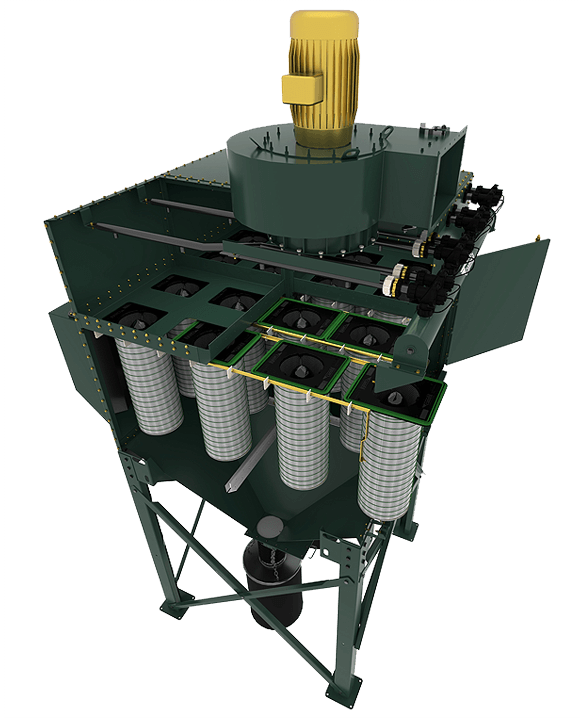

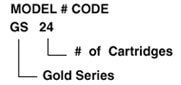

Gold Series industrial dust collectors are the industry’s best-in-class dust collection systems. The family includes Gold Series and Gold Series X-Flo collectors, which have a 25-year track record of successful performance around the world. They handle all kinds of toxic and combustible dusts, smoke and fumes, including fine, fibrous and heavy dust loads.

Built for unwavering dependability, reliability, and protection, Gold Series collectors drive clean air and confidence—even under the toughest conditions. They combine high dust-processing capacity with low pressure drop to deliver maximum airflow and efficiency all within a compact footprint. An advanced baffle configuration distributes larger particles before they reach the filters, extending filter life and minimizing maintenance. The result? Fewer change-outs, reduced downtime, and a lower total cost of ownership.

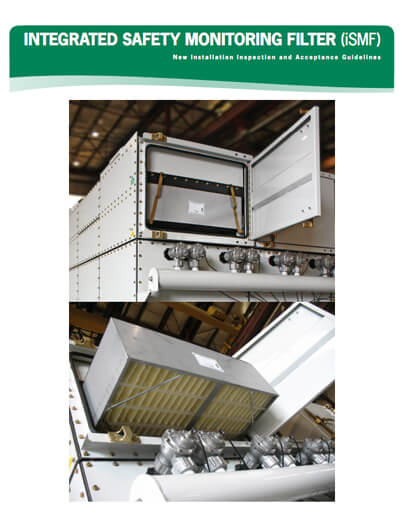

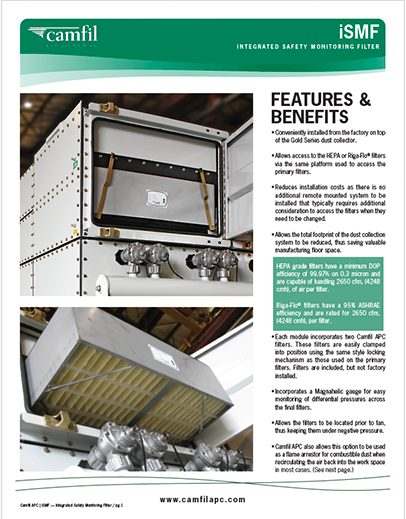

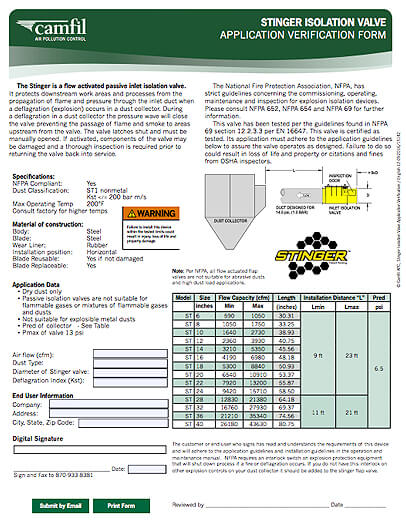

And most importantly, they exceed OSHA mandates for factory air quality and safety. When equipped with Camfil’s explosion protection equipment such as explosion vent, iSMF (Integrated Safety Monitoring Filter), and Stinger explosion isolation valve, Gold Series III collectors provide the highest exposure, fire hazard and combustible dust explosion protection in accordance to both NFPA and ATEX standards.

Key Features of Gold Series Industrial Dust Collectors

Processes the maximum CFM of dust-laden air from industrial processes.

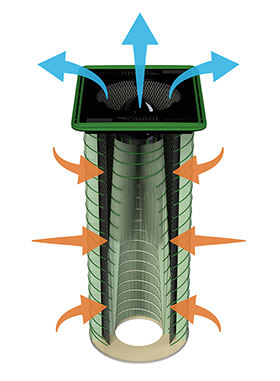

OptiCone filter cartridges have open-bottomed inner cones that greatly expand the usable surface area of the cartridge. This configuration ensures that pulsed air is evenly distributed from top to bottom, delivering more efficient cleaning across the entire filter.

An advanced baffle configuration distributes particles evenly across the unit after separating the largest ones towards the hopper before they reach the filters, extending filter life and minimizing maintenance.

Engineered to protect workers from occupational exposure and combustible dust explosions. Gold Series collectors with explosion protection systems exceed NFPA and ATEX standards.

With each pulse, maximum dust is ejected out of the filters towards the collection bin, which maintains a low pressure drop. Unlike horizontal cartridges, this design directs dust into the hopper instead of onto cartridges below.

Discover More – Connect With Our Team

The Industry’s Lowest Cost of Ownership

Gold Series industrial dust collectors use crossflow technology to create a uniform airflow that extends the life of your filter cartridges and minimizes energy usage.

Filters last longer and require fewer change-outs, reducing your total cost of ownership. All Gold Series collectors are built modularly, and GS X-Flo collectors accommodate higher-capacity filter cartridges in each module for a better industrial dust collection system.

Optimized Design Advantages

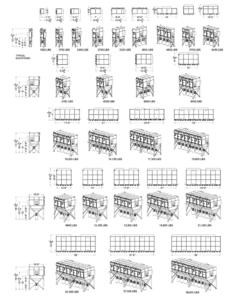

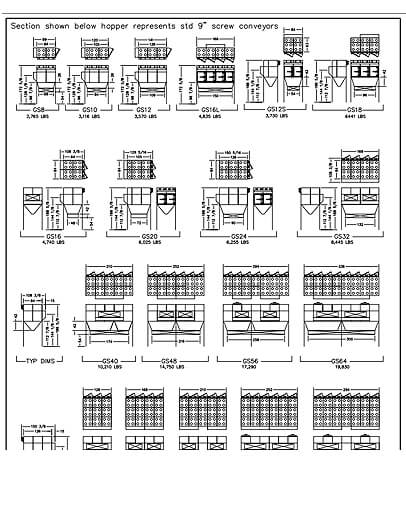

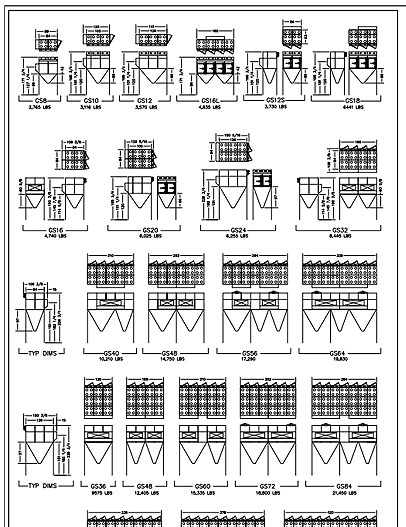

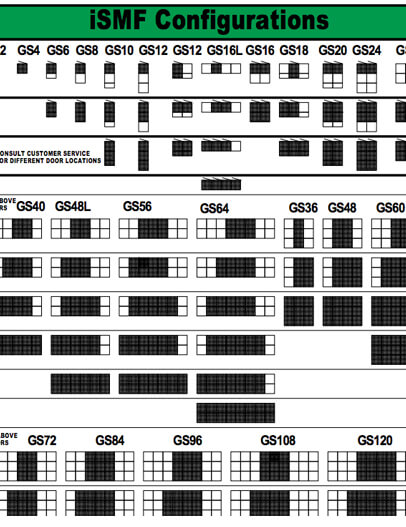

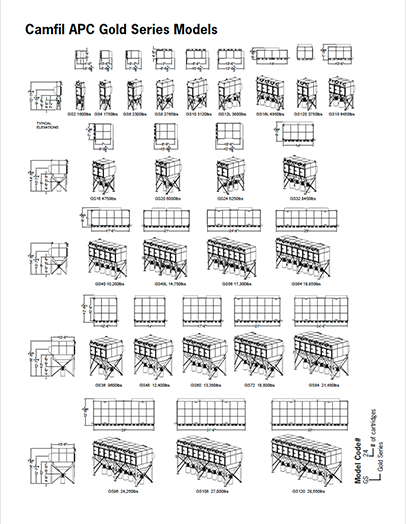

Modular Design

It’s easy to customize Gold Series industrial dust collectors for your specific work environment. Individual modules contain four filters and accommodate airflows up to 6,000 CFM, providing a near-limitless variety of configurations and airflow capabilities. You get fast delivery of an industrial dust collection system that is just right for your application and space.

More Filter Media, Same Footprint

OptiCone™ filters use our proprietary inner pleat pack. This open-bottomed, inner cone of media greatly expands the usable surface area of the cartridge. Our proprietary OmniPleat packs stay cleaner and last longer than conventional filters. Synthetic beads on both sides of the pleat pack keep the pleats evenly spaced, which exposes more media to the airstream, so more dust is captured and easily released during pulse cleaning.

Vertical Filter Cartridges

OptiCone™ filter cartridges are positioned vertically in the dust collectors. With each pulse, maximum dust is ejected out of the filters towards the collection bin, which maintains a low pressure drop. Unlike horizontal cartridges, this design directs dust into the hopper instead of onto cartridges below.

Cleaner, Safer, More Efficient

Upgrade to the Gold Series Dust Collector

Built to Perform

Gold Series dust collectors are built to set the standard with 25 years of proven reliability

Gold Series industrial dust collectors have a modular design for maximum flexibility. Each module accommodates airflows up to 5,000 CFM each. Component configurations are virtually unlimited.

Gold Series industrial dust collectors have a modular design for maximum flexibility. Each module accommodates airflows up to 5,000 CFM each. Component configurations are virtually unlimited.

A GS24 with platform and ladder, silencer, blast plate, and custom door setup.

GS24 model with explosion vents and integrated HEPA filter.

Gold Series with directional explosion vent and integrated SMF.

Multiple GS units with platform and ladder options and explosion vents.

Applications Include:

- Chemical Processing – Plastics, paper, fiberglass, other composites

- EHS (Environmental, Health, Safety) – Dust, fume, and workplace air quality control

- Engineering – Industrial processes and system design

- Food & Beverage – Seed processing, cereals, spices, grains, flours, starches

- Grain, Feed & Seed – Grain handling, processing, and storage

- Mining – Copper, rock crushing, venting of storage, excavating

- Metalworking:

- Packaging – Bagging, filling, and material handling

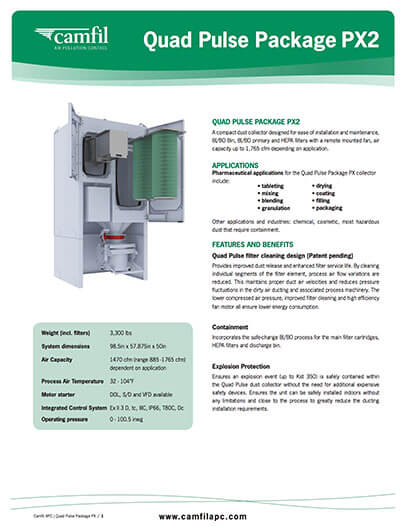

- Pharmaceutical – Tablet coating, tablet pressing

- Powder & Bulk – Covers chemical, food, and pharma markets

- Woodworking – Sawing, sanding, routing, cutting

Español

Español