Manufacturers and processing facilities that produce large amounts of dust and fumes rely on cartridge-style industrial dust collectors to keep their workers safe and maintain compliance. Although these facilities have to meet the same environmental health and safety requirements for dust control, each building’s unique design/layout/blueprint may force specific dust collection system design.

Many dust collectors are built as one large welded assembly, which can make them challenging to install in confined areas and in processes that have limited floor space. One large assembly also makes it challenging to upgrade the collector when dust handling needs change. Fortunately, there is a more cost-effective option.

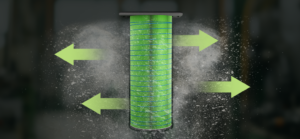

Dust collectors can also be built from smaller square modules that are bolted together. These modules offer more flexibility because they can be combined into dozens of different configurations to fit the specific work environment and required air volume. Below are a few examples of how a modular dust collector can solve some complex floor space challenges.

Modular Dust Collectors are Easy To Move Around the Factory Floor

Traditional (non-modular) dust collectors are assembled and welded together in a factory and then shipped to their destination in one large piece. If the collector must be installed on an upper floor and the facility does not have a large enough service elevator, the dust collector must then be disassembled, moved, and reassembled at the desired location.

Traditional (non-modular) dust collectors are assembled and welded together in a factory and then shipped to their destination in one large piece. If the collector must be installed on an upper floor and the facility does not have a large enough service elevator, the dust collector must then be disassembled, moved, and reassembled at the desired location.

Modular dust collectors like the Gold Series X-Flo are built from square modules that can be bolted together on site. If an overhead crane is not an option because of height limitations, you can use a forklift to move the dust collector through the building to the desired location in small sections.

No Hot Work Permits Required

Every job site in the U.S. that engages in hot work outside of a designated area (like a weld shop) requires a permit. The permit provides documented proof that the facility put the required safety measures in place to avoid a fire. These permits must be obtained before work begins.

Because modular dust collectors are assembled with bolts and can be built on site, no welding or hot work permits are required. This can save production time. This is especially important for facilities that produce combustible dust, because the assembly process does not introduce an ignition source.

A Dust Collector Sized to Fit Your Specific Needs

In order to achieve maximum efficiency, a dust collector must be properly sized to run dependably at the required airflow for your specific dust and application. Building constraints may force some facilities to use an undersized dust collector that is not a good fit for their operations. Using undersized collectors can cause serious issues like high operating pressure, overloaded filters, and frequent filter changeouts. These issues often cause operating costs and energy usage to be higher for a smaller unit than for a larger one.

Modular dust collectors help to solve this issue because they can be built in a variety of configurations to fit space constraints. Because filter cartridges are mounted in frames inside modules, the modules can be arranged with single boxes forming a row, L-shape, square or rectangle. Dust collector modules can even be located separately around the plant.

Various modifications that are possible with a modular industrial dust collector like the Camfil APC Gold Series X-Flo.

As Your Operations Grow, So Can Your Modular Dust Collection System Design

In addition to the shape options available for modular dust collector systems, you can also change inlets and outlets onsite by simply bolting and unbolting. This is convenient if the scope of work changes, requiring dust collector modifications. You can add modules as your production volume grows and produces a higher volume of dust.

With a modular dust collection system, you can also add and change items like ducting and explosion protection equipment. And if facility upgrades or remodels are in the future, you can be reconfigured and move the system.

Specifying a modular dust collection system is a cost-effective strategy that provides the most design flexibility. The specialists at Camfil APC will work with you to design a system that meets your facility’s specific airflow, space and safety requirements. For more information on integrating a modular dust collection system into your facility, contact us today.

Americas

Americas