Purchasing a replacement dust collector filter may seem like a simple task: just find the lowest priced product with the required efficiency rating that fits your collector. But filters with the lowest purchase price don’t provide the best dust collector performance or the lowest total cost. That's because the primary costs associated with filters are energy usage, maintenance and change-outs, and those costs are dramatically affected by filter quality.

Compare it to products you buy for your car: Would you rather purchase a $10 oil filter for your car that lasts one month or one that costs $20 that lasts for a hear and helps your car perform better and use fewer gallons of gas each week? The purchase price becomes less important than the overall savings possible with a premium product. Investing more in quality filters with the right type of media for your application cuts costs because they last longer, use less energy and allow your dust collector to operate more efficiently.

Determining the best overall value requires a closer look at the dusts you are dealing with and your specific application. Only by analyzing all the associated costs and benefits can you determine the true filter cost and achieve significant long-term savings.

Know Your Dust

Different types of dust have unique characteristics that affect the filtration that is required to comply with regulatory standards. You need to know these characteristics, you can't select the most appropriate filter design or media.

For example, toxic dusts such as hexavalent chromium are known carcinogens. For hex chrome, OSHA has set thresholds as low as 5 micrograms (0.005 milligram) per cubic meter TWA (time-weighted average). This is 10 times stricter than the limits for some other toxic dusts and would require that your dust collector be equipped with high-efficiency media to maintain the permissible exposure limit (PEL.)

Next, take into consideration the sizes and shapes of the dust particles, if dust is combustible, if it is sticky or dry, etc. These characteristics help to determine the most appropriate filter media. Testing a sample of dust is the only way to get an accurate assessment of dust properties. Dust testing is available from independent laboratories and many equipment suppliers.

Differential Pressure and Pressure Drop

Differential pressure is an important element of filter performance and cost because it determines when filters require cleaning and replacement. As dust builds on a filter cartridge, airflow becomes more restricted and the dust collector has to work harder to pull the air through the cartridge.

That's why dust collectors monitor differential pressure - the pressure difference between the clean-air and dirty-air section of the collector. When pressure drop rises to a set level, it triggers the system to "blast" compressed air through the cartridge to dislodge the dust so it can fall down into the hopper. Most of the dust falls away with pulse-cleaning, but not 100%. That's why filter cartridges don't last forever. Pressure drop slowly rises over time, eventually requiring filter change-out.

Filter Design and Pulse Cleaning

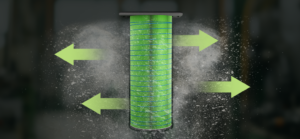

A dust collector's cleaning system works in conjunction with filter design. As dust builds up on the filter, the collector automatically pulse-cleans every few seconds so the dust collector doesn't have to be taken offline.

When it comes to media, more is not necessarily better. Many filter manufacturers add media to each cartridge so they can report a higher square meters of media. But the trade-off of more media is tighter packed pleats to fit more media in the same space. This configuration negatively affects dust collector performance. With tightly-packed pleats, much of the media is never exposed to the airstream, so dust only collects on the edge of pleats. Also, any dust that manages to get between those pleats is hard to get out. The dust collector's reverse pulse cleaning system can’t eject it.

The key is to use filter cartridges with an open pleat design where 100 percent of the media is usable. Open pleats allow the collected dust to release from the filter, keeping the resistance lower through the filter for a longer time. Camfil HemiPleat filters use a patented pleating technology that places synthetic bead pleat separators on the pleat tips to ensure they stay open. These separators enhance dust-release and prevent the media from folding over on itself, which could cause the filter to plug. Filter designs that feature uniform, open pleats last longer, maintain low-pressure drop and require less frequent change-outs.

The key is to use filter cartridges with an open pleat design where 100 percent of the media is usable. Open pleats allow the collected dust to release from the filter, keeping the resistance lower through the filter for a longer time. Camfil HemiPleat filters use a patented pleating technology that places synthetic bead pleat separators on the pleat tips to ensure they stay open. These separators enhance dust-release and prevent the media from folding over on itself, which could cause the filter to plug. Filter designs that feature uniform, open pleats last longer, maintain low-pressure drop and require less frequent change-outs.

Understanding Total Filter Cost

When shopping for dust collector filters, it’s important to calculate the Total Cost of Ownership (TCO) using a step-by-step evaluation process of the following costs:

Energy: How much energy does the dust collector consume on a daily basis including electrical costs, compressed air usage, and CO2 emissions? How do different filter designs and media affect energy usage?

Energy: How much energy does the dust collector consume on a daily basis including electrical costs, compressed air usage, and CO2 emissions? How do different filter designs and media affect energy usage?- Consumables: What dust collector parts need to be replaced periodically as part of normal usage over the lifetime of the machine? Will certain filter designs and media better protect the collector so that these parts last longer?

- Maintenance and Disposal: How much downtime and labor will be required each time a filter is changed out? What is the cost of this downtime and labor? How do the disposal requirements and costs vary for different filter options?

- Long-term filter costs: Don't forget to factor in the lifespan of each filter option and the costs to purchase replacement filters. Also, consider the cost of transporting and inventorying filters. Will certain filters require less frequent replacement and therefore lower replacement cost over the long run?

Whether you’re shopping for a whole new dust collection system or simply just looking for the most cost-effective replacement filters for your current system, evaluating the TCO can yield useful information.

To learn more about how you can save on dust collector filter costs over time, download our TCO white paper now.